Valtek FlowTop General Service Valve FCD VLENIM8610A4 11/18

11

flowserve.com

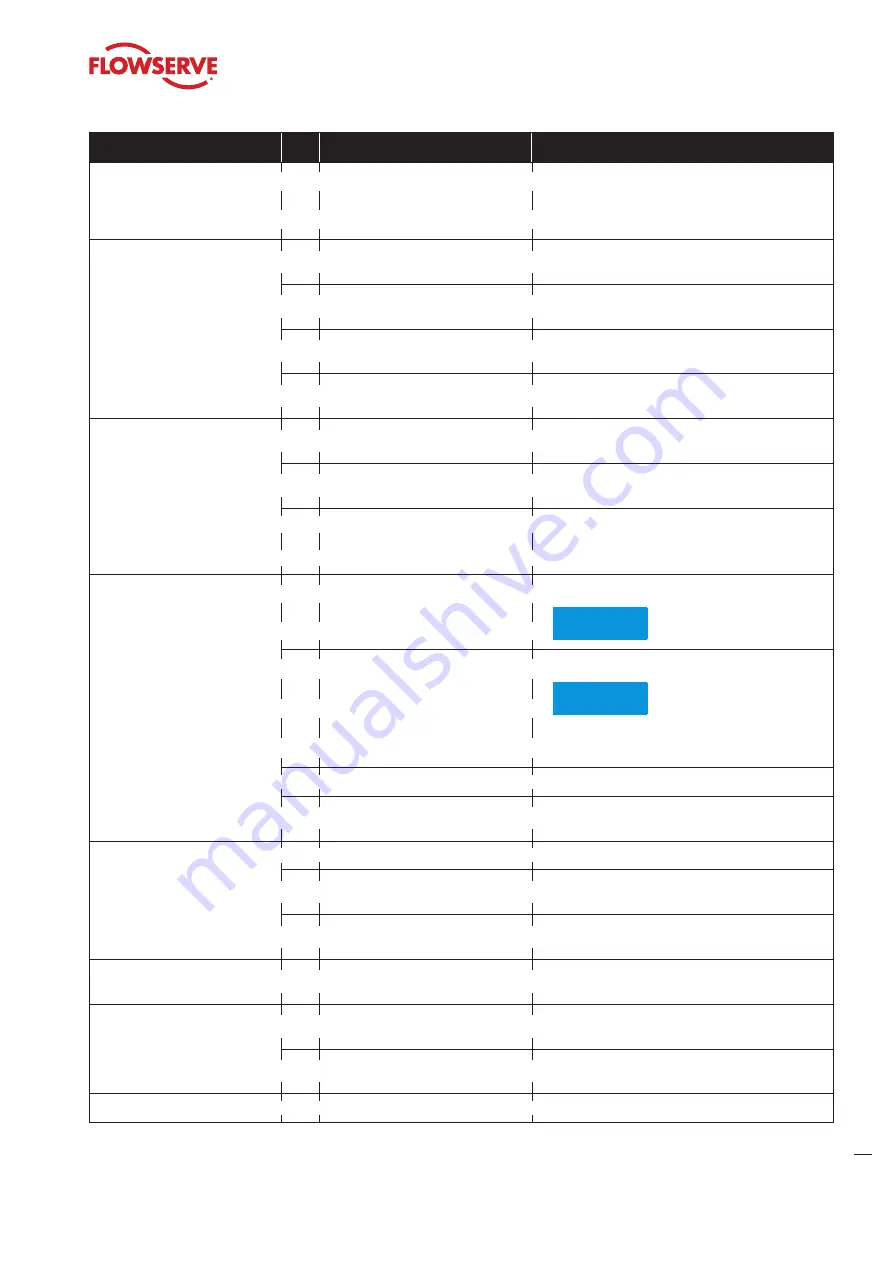

Defect

No.

Possible Causes

Remedy

Jerky stem movement

2.2

• Actuator not powerful enough

• Compare actuator specifications on the serial

plate with operation specifications of the facility. If

incompatible, contact customer service department

or contract partner

Stem travel less than full stroke

(0 to 100 %)

3.1

• Air supply pressure too low

• Provide air at the pressure stated on the serial plate

(European production only).

3.2

• Pneumatic actuators:

Improper handwheel position

• Move handwheel to limit position , otherwise

contact factory for information.

3.3

• Improperly adjusted or defective

positioner

• Readjust positioner to positioner manufacturer‘s

specification

3.4

• Foreign particles in valve seat or

damaged trim

• Contact customer service department or contract

partner

Excessive valve seat leakage

4.1

• Damaged sealing surfaces on

valve seat or plug

• Contact customer service department or contract

partner

4.2

• Foreign particles in seat area

• Contact customer service department or contract

partner

4.3

• Plug does not close fully

• Refer to No. 3.1 to 3.5

Leaking packing box system

5.1

• Compression force on packing box

too low

• Slightly retighten packing box

NOTICE

Make sure stem can still move.

5.2

• Worn packing

• Slightly retighten packing box

NOTICE

Make sure stem can still move.

If the packing does not stop leaking, contact

customer service department or contract partner

5.3

• Dirty stem

• Clean stem with suitable cleaning agent

5.4

• Damaged stem

• Contact customer service department or contract

partner

Leaking bonnet gasket

6.1

• Gasket compression is too low

• Properly retighten bonnet bolting nuts crosswise

6.2

• Gasket defective

• Contact customer service department or contract

partner

6.3

• Corrosion

• Contact customer service department or contract

partner

Leaking body

7.1

• Corrosion or high velocity related

damage

• Contact customer service department or contract

partner

No limit switch signal

8.1

• Power supply to limit switch

interrupted

• Check power supply

(connections, circuit breakers, voltage)

8.2

• Limit switch out of adjustment

• Readjust limit switch operating distance; see limit

switch data sheet

Unstable positioner

9.1

• Defective positioner

• See user instruction of the positioner manufacturer

Table 8: Trouble-shooting