5

Flow Control Division

Kammer Control Valves

6

PRESSURE TESTING PIPING SECTION

The valve has already been pressure-tested by the

manufacturer. When pressure testing a section of the

pipeline with valves installed, observe the following:

6.1

First thoroughly flush newly installed piping systems to

remove all foreign objects.

6.2

Valve opened: The test pressure should not exceed the

value of 1.5 x PN (according to nameplate):

6.3

Valve closed: The test pressure should not exceed the

value 1.1 x PN (according to nameplate).

If a leak occurs on the valve, observe Section 8

“Troubleshooting”.

CAUTION:

If the flange connection with plastic liner

leaks:

First retighten flange connection to torque specified in

Table 1a or 1b in Section 5.6 (installation).

If the flange connection is still leaks:

Loosen flange connection. Check the flange connection

to ensure that it is smooth and parallel.

Check the sealing surfaces on both flanges: When the

inner lining is damaged, replace valve and/or

counterflange.

7

NORMAL OPERATION AND MAINTENANCE

These installation, operating and maintenance

instructions cannot contain all detailed information on

all possible versions for reasons of clarity and, in

particular, cannot take into consideration all imaginable

cases for setup, operation and maintenance. Therefore,

only primarily instructions are contained, which are

required for the intended use in industrial applications.

If anything is not clear, particularly if any detailed

information on the specific product is missing, clarify as

r e q u i r e d w i t h t h e r e s p o n s i b l e F L O W S E R V E

representative.

8

TROUBLESHOOTING

When troubleshooting or during general maintenance,

always observe Section 1 “Safety precautions”.

DANGER:

If a valve contaminated with dangerous

substances has to be removed from the system or

pipeline, decontaminate it properly before performing

further maintenance work.

9

PODUCT DESCRIPTION

9.1

Housing

The body material is made of GGG40.3 (standard), other

body materials are also available from the manufacturer

on request. For valve bodies with plastic liners: See

Table 2b for coating materials.

The liner thickness is at least 5 mm for DN25 and higher

and 3.5 mm for DN15 and DN20.

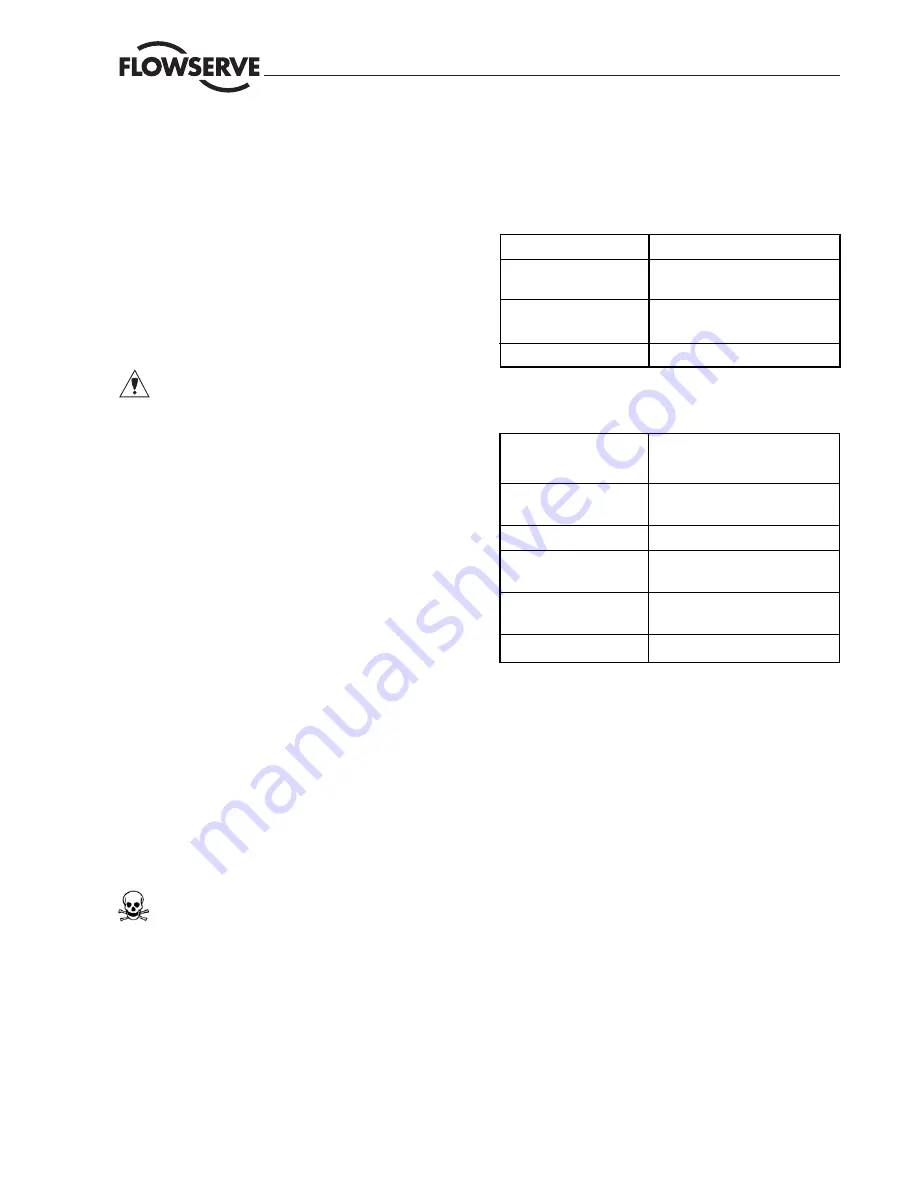

Table 2a: Body specifications

Body material

0.7043 (GGG40.3)

Pressure class

PN16

End connections

DIN PN 16

(flanged)

ANSI Class 150

Liner thickness

4 – 6 mm

Table 2b: Liner materials

PFA

Perfluoralkoxypolymer

(Standard)

PFA conductive

Perfluoralkoxypolymer,

electrically conductive

PVDF

Polyvinilidenfuoride

ETFE

Ethylene Tetrafluorethylene –

copolymer (Tefzel

®

)

FEP

Tetrafluorethylene –

Perfluorpropylene

PP

Polypropylene

10

BONNET

The bonnet is connected with a form fit to the valve body

providing, on the one hand, a potential compensation

between the housing and bonnet and on the other a

defined compression force for the body seal and

bellows. The bonnet is provided with a blowout safety

system. This means that the valve stem cannot be

pulled or pressed upward out of the bonnet.

11

PLUG AND SEAT

The seat and plug are screwed, i.e. replacement is

possible at any time when the Kvs value changes or for

repair. The plug is screwed to the bellows and secured

against loosening by a PTFE insert. For smaller Kvs

values, a Hastelloy insert can be provided in the plug as

well as in the seat (see Table 3).

The possible material combinations and available Kvs

values and curves are shown in Table 3.