MN301520 Rev A1

15

|

Application Examples

Step

Seven

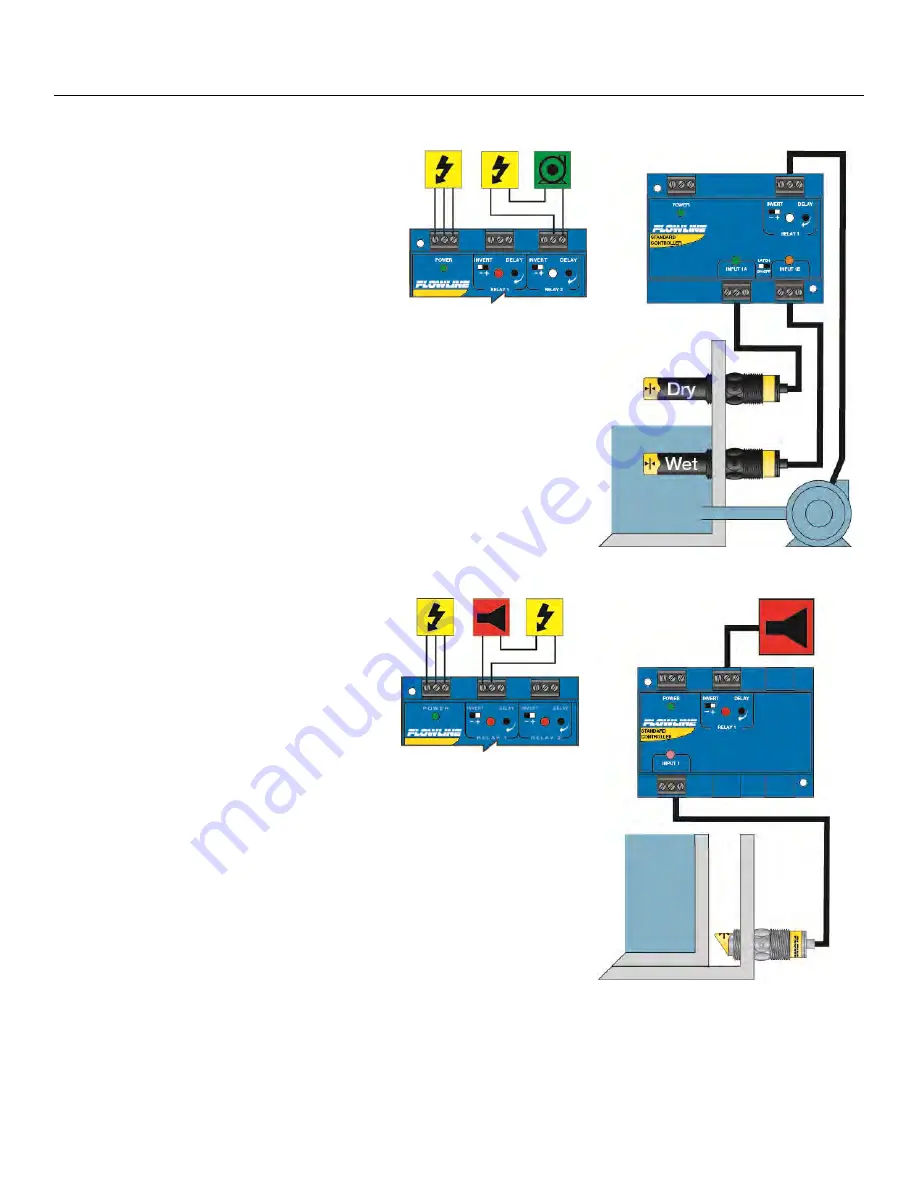

AUTOMATIC EMPTY:

Similar system logic can be used for an

automatic empty operation. In this example,

we will use a pump to empty a tank. The

system still consists of a tank with a high level

sensor, a low level sensor, and a pump that is

controlled by the controller.

Note:

Fail-safe design is critical in an

application where the tank is passively filled.

A power failure to the controller or the pump circuits may cause the tank

to overflow. A redundant high alarm is critical to prevent an overflow.

Connect the pump to the NO side of the relay. In this case, Invert

should be OFF, when the relay is energized, the pump will run and

empty the tank. The relay indicator will correspond directly to the on/off

status of the pump.

Note:

If the pump motor load exceeds the rating of the controller’s

relay, a stepper relay of higher capacity must be used as part of the

system design.

LEAK DETECTION:

A leak detection switch is installed either

inside the interstitial space of the tank or

through the outer wall. The switch will

remain wet 99.99% of the time. Only when

liquid comes into contact with the switch will

the relay close to activate an alarm.

The alarm is connected to the NC side of the

relay to allow for a power failure alarm.

Note:

The sensor is normally dry. In this condition, we want the relay

to be energized so the alarm does not sound: i.e., the Red relay LED

should be on whenever the Input LED is Amber. So we turn Invert On.

If liquid comes into contact with the switch, the switch activates, the

relay de-energizes, and the alarm sounds.