GB

GB

20

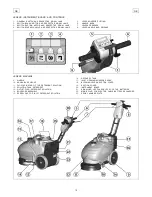

6. Holding the handle bar firmly, lift the front

part of the machine making it rotate on the

rear wheels bringing it into the vertical position

as shown in the figure.

BRUSH CLEANING

Disassemble the brush and clean it with a

water jet (for the disassembly see here after

under “BRUSH DISASSEMBLY/ASSEMBLY”).

BRUSH DISASSEMBLY/ASSEMBLY

1. Tip over the machine backwards (see

under “POSITIONING OF THE MACHINE FOR

MAINTENANCE AND PARKING") paying

attention to remember to switch off the general

switch and to empty the tanks before tipping

over the machine.

2. With the machine in this position rotate the

brush clockwise, as indicated in the figure,

until it is released from their seats of the

brush holder plate.

3. To reassemble the brush insert the coupling

buttons into their seats of the brush holder

plate and rotate counterclockwise until it gets

blocked.

ATTENTION:

The handling of the brushes operation must be

carried out using suitable gloves to protect

both mechanically from contact with the bristles

and the chemical risk of contact with

dangerous solutions.

SQUEEGEE CLEANING

Keeping the squeegee clean guarantees always

the best drying action.

1. Tip over the machine backwards (see

under “POSITIONING OF THE MACHINE FOR

MAINTENANCE AND PARKING") paying

attention to remember to switch off the general

switch and to empty the tanks before tipping

over the machine.

2. With the machine in this position clean with

care the internal part of the squeegee inlet

eliminating eventual dirt residuals and clean

with care the squeegee rubbers.

ORDINARY MAINTENANCE

CONTROL DEVICE BRUSH WEAR

A safety device stops the brush motor when

the brush reaches a low bristle level of about

10mm such that a good cleaning result is not

guaranteed and to prevent floor damages.

To restore the working functionality of the

machine it is necessary to replace the brush

(see

under

“BRUSH

DISASSEMBLY/ASSEMBLY”).

BRUSH REPLACEMENT

The brush has to be replaced when the

control device brush wear intervenes. It is

possible to use also other brush types,

depending on the type and dirt of the floor to

be cleaned (see under “RECOMMENDED

BRUSHES”).

Disassemble the old brush and replace it with

a

new

one

(see

under

“BRUSH

DISASSEMBLY/ASSEMBLY").

REAR SQUEEGEE RUBBER REPLACEMENT

Check the squeegee rubber wear and

eventually turn or replace it.

For the replacement it is necessary to:

1. Lower the squeegee rotating to the lower

part the handle lever (5) placed in the

centre of the handle bar.

2. Tip over the machine backwards (see

under “POSITIONING OF THE MACHINE FOR

MAINTENANCE AND PARKING") paying

attention to remember to switch off the general

switch and to empty the tanks before tipping

over the machine.

3. With the machine in this position act upon

the wing nuts (1) unscrewing them completely

to free the squeegee.

4. Take off the coupling (2) of the squeegee

hose and take off the squeegee.

5. Release the hook (4) of the rubber holder

blade and take the rubber off to turn it to a

new side or replace it.

6. Check that the coupling and the squeegee

hose are not obstructed and eventually take off

the dirt.

To reassemble the squeegee repeat reverse

the operations above-mentioned.