12

OPERATION

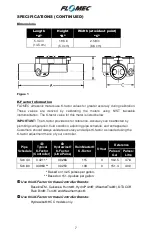

Each QS100-10 meter is shipped with the K-factor and other information permanently

marked in a rectangular recess on the coverplate.

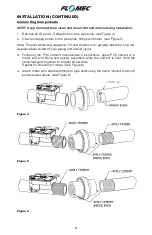

LEDs Functionality

There are two LEDs on the QS100-10 meter. The GREEN LED is used to indicate basic

power and functionality of the meter. The AMBER LED is used to indicate that there is

a flow of water through the QS100-10 meter. The LEDs will behave in the following

manner to indicate di

ff

erent modes of operation:

MODE

LED BEHAVIOR

Power Disconnected

or Meter Failure:

Both GREEN and AMBER LEDs are OFF.

No Flow Low Power

Mode:

GREEN LED flashes ON/OFF at a rate of

approximately 2 blinks per second.

No Flow or Reverse

Flow Active Mode:

GREEN LED flashes ON/OFF at a rate of

approximately 8 blinks per second.

Low Flow Active

Mode:

GREEN LED flashes ON/OFF at a rate of

approximately 8 blinks per second and the

AMBER LED flashes ON/OFF at a rate that is

proportional to the rate of water flow thru the

meter.

**High Flow Active

Mode:

GREEN LED flashes ON/OFF at a rate of

approximately 8 blinks per second and the

AMBER LED will appear to be constantly ON, but

will be dim.

**NOTE:

To save power it is normal for the LEDs to be dim when flashing at

higher flow rates. At very high flow rates, the AMBER LED will appear to be

constantly ON but dim.