Protect yourself and others by observing all safety

information. Shut off power and drain pressure from

system prior to service.

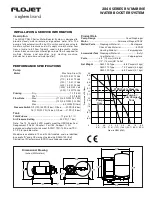

Mounting

The FLOJET 2840 Series Water Pressure System should

be mounted in a dry and adequately ventilated area.

Select a location where the plumbing is as direct as

possible and the inlet strainer is visible and accessible

for cleaning.

The unit can be deck or bulkhead mounted. If bulkhead

mounted, the pump head should be down or lower than

the motor.

Fasten base securely with the four rubber mounting feet

assembled to base as shown below.

Plumbing

Fasten strainer in a visible and accessible location for

future cleaning. Use 3/4” (19 mm) I.D. hose between

pump inlet & strainer. Connect strainer inlet to water

supply line from tank and clamp all hose connections

securely to avoid air leaks.

City water supply may be connected at any location in

the pressurized cold water line.

GENERAL SAFETY INFORMATION

ELECTRICAL

RISK OF AN ELECTRICAL SHOCK!

When wiring an electrically driven pump, follow all

electrical and safety codes, as well as the most recent

National Electrical Code (NEC) and the Occupational

Safety and Health Act (OSHA).

RISK OF PRODUCT DAMAGE!

Make certain the power source conforms to the pump

voltage. Be sure all power is disconnected before

installation or removal.

For 12 VDC, 24 VDC and 32 VDC models, the red wire is

positive and black is negative. Use the maximum

recommended fuse for pump protection. Recommended

fuse amp rating is located on pump label. Failure to

provide correct overload device may result in motor

failure.

For 115 VAC models plug AC cord into a conventional

115V AC outlet.

OPERATION

IMPORTANT

- For correct operation, the tank must be

properly pressurized on the air side

before

pump is

started. Follow instructions on the tank label and check

air pressure after filling and before starting the pump.

The air valve is standard tire valve. Compressed air hose

or hand pump may be used to pressurize. Pressure can

be reduced by pressing the center pin in the valve.

To start up the Water Pressure System, make sure water

supply tank is at least 1/4th full and is open to pump

inlet. Open all valves or taps on outlet side to purge air

from the system. Turn power on to the pump, pump will

start up. Allow to pump for a minute or until all the air

has been purged from the system. Close all valves in the

system, the pump will pressurize the tank, shut off and

operate automatically to maintain pressure in the

system.

To completely fill the pressure tank for maximum

volume, shut off power to pump and open faucet (or

valve) closest to tank. Trapped air will be expelled. Turn

on power to pump.

City Water

Inlet

Water

Tank

Autofill Tank Valve,

Plumb to Tank

Check

Valve

Water Pressure

System

Water

Heater

Do Not Plumb Autofill

to Pump Suction Line

Vertical

Horizontal

DO NOT USE PUMP IN A FLAMMABLE

ENVIRONMENT DO NOT USE TO PUMP

FLAMMABLE OR EXPLOSIVE FLUIDS

SUCH AS GASOLINE, FUEL OIL,

KEROSENE, ETC.

WARNING

WARNING