SINCE 1981

PLATE AND FrAME - HEAT ExCHANgErS

3

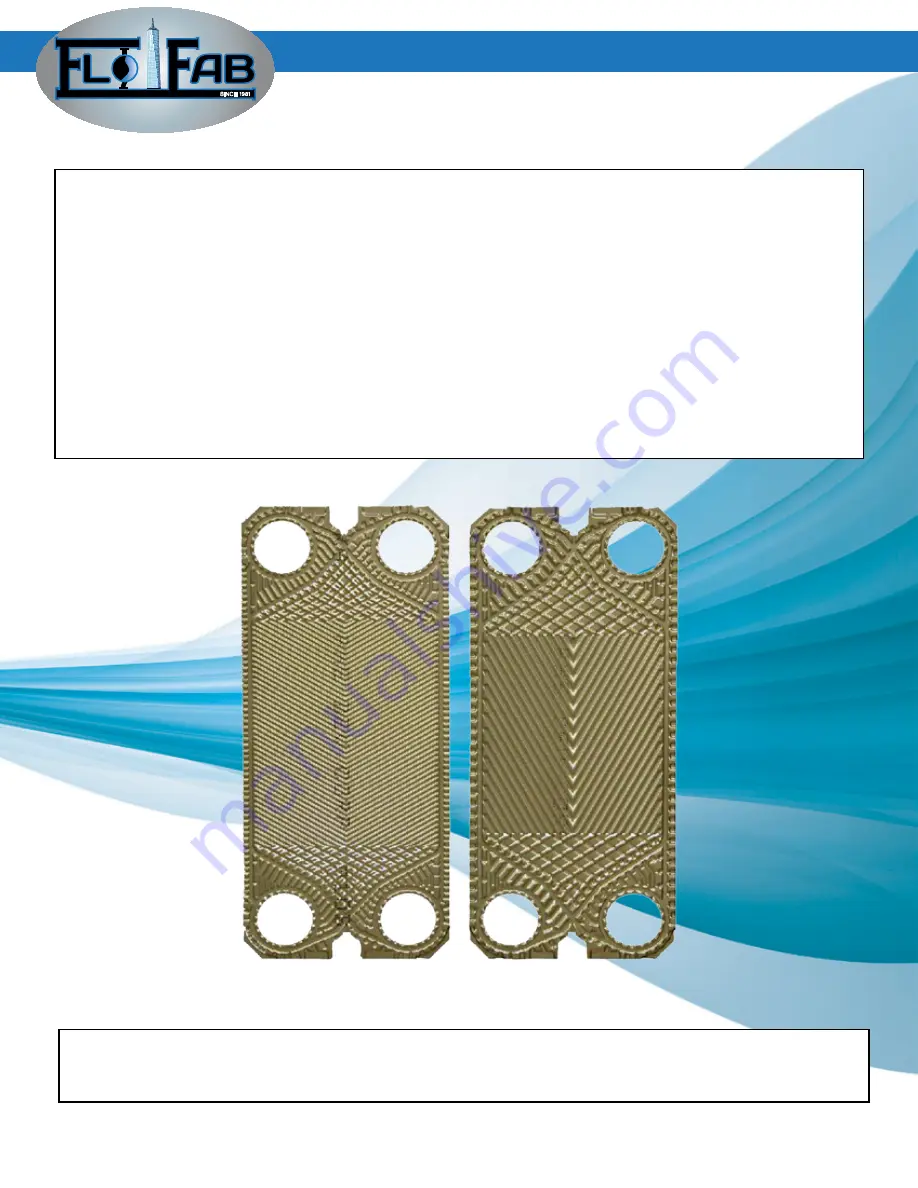

The heat exchanger plates, which make up the heat transfer surface, are clamped between two

plates of steel with the use of the tightening bolts. The heat exchanger construction allows

a plate heat exchanger to be easily opened for inspection and cleaning.

The plate pattern is corr

ugated and varies depending on the application and the fluids being put

through the heat exchanger. As the plate’s corrugation depth gets smaller the thickness of the

plate can be less.

Each heat exchanger plate is formed by pressing in one piece (no seams or welds).

Most plates have four holes punched, one in each corner. The last plate in a single pass

unit has no holes so the fluid flow is reversed or turned. Multiple pass heat exchangers have

turning

plates with only two holes for redirecting the fluid flow.

Flo Fab heat exchanger plates are made with two different pressing patterns – one is charac-

terized by an obtuse angle giving a high theta plate, the other with an acute angle giving a

low-theta plate.

2.2 Plates

HIgH-THETA PLATE

LOW-THETA PLATE

Between two adjacent plates a flow channel is formed with the aid of the gasket. The liquid flows

straight up or down or in parallel flow. No liquid flows between the plates adjacent to the fixed

cover and the moveable cover plate.