10

© Copyright 2016. All rights reserved.

MAINTENANCE

LUBRICATION

The pump and motor requires no lubrication. The

ball bearings of the motor have been greased at

the factory. Under normal operating conditions

they should require no further greasing.

ROTARY SEAL ASSEMBLY REPLACEMENT

CAUTION:

Make certain that the power

supply is disconnected before attempting to

service the unit. The rotary seal assembly must be

handled carefully to avoid damaging the precision

lapped faces of the sealing components.

See Parts List For Reference Letters

1. Disengage pump body

G

from motor assembly

by removing bolts

H.

2. Remove diffuser

D.

3. Unthread impeller

C

from motor shaft and

remove spring.

NOTE:

To remove impeller, place screwdriver

within slot in shaft end and hold shaft firmly.

Rotate impeller counterclockwise to remove from

shaft.

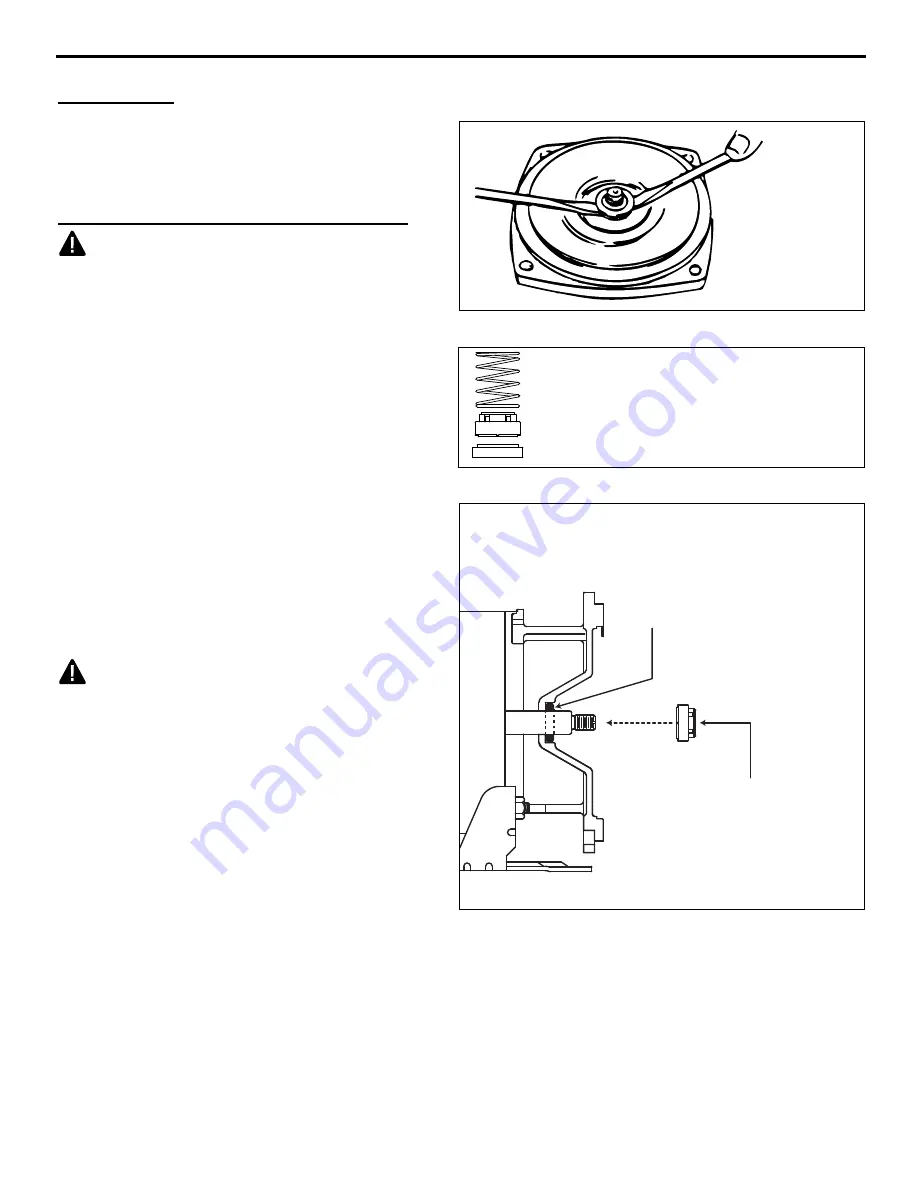

4. Use a screwdriver to remove the rotary seal

B.

Pry the ceramic seal and rubber gasket from

the recess of the mounting bracket. (Fig 1).

CAUTION: Be careful not to damage the

motor shaft or recess surface.

5. Clean the recess and motor shaft thoroughly.

6. Install the new rotary seal assembly (Fig 2):

NOTE:

To make installation easier, apply a drop

of liquid soap to the outside diameter of the rubber

gasket. Make certain that the ceramic seal is kept

clean and free of dirt and/or oil.

a. Insert the ceramic seal and the rubber

gasket into the recess. (Fig 3).

b. Slip the remaining parts of the rotary seal

assembly onto the motor shaft.

7. Replace the spring, impeller, and diffuser

removed in steps 2 and 3.

8. Reassemble the pump body to the motor and

mounting bracket.

Fig 1

Fig 3

Remove

Mechanical

Seal

Press ceramic

and gasket into

housing

Press rotary

seal onto shaft

against ceramic

Ceramic seal and rubber gasket

Rotary seal half

Stainless steel spring

Fig 2 - Rotary Seal Assembly