Printed in Canada

TAC1000 Manual

June 19, 2013

Page 5

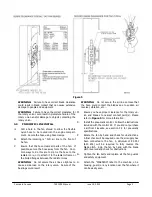

Figure 5

WARNING:

Failure to have correct blade clearance

could result in blade contact that can cause extensive

damage to people and equipment.

WARNING:

Failure to have the correct clearance for

the rotary union could result in premature failure of the

rotary union and/or damage to objects contacting the

rotary union.

3.0

PNEUMATIC LINE INSTALL

A.

Drill a hole in the fan shroud to allow the flexible

nylon hose to be routed into the engine compart-

ment. Secure the hose using hose clamps.

B.

Attach the incoming ¼” O.D. air line to the front of

he fan.

C.

Ensure that the hose clears all parts of the fan. If

possible, secure the hose away from the fan. Com-

mon ways to do this are to zip tie the hose to the

radiator core, or to attach it to the radiator frame or

the bolted flanges between the radiator cores.

WARNING:

Do not secure the air line so tight as to

cause a side load on the rotary union. Failure of the

bearings could result.

WARNING:

Do not secure the air line so loose that

the hose could contact the blades due to sudden air

reversal, vibration, etc...

D.

Ensure you have proper clearance for the rotary un-

ion and blades to nearest contact point(s). Please

refer to

Figure 5

for more information.

E.

Install the pneumatic control. Follow the instructions

included with the control kit. If you did not purchase

a kit from Flexxaire, see section 3.2 for pneumatic

specifications.

F.

Rotate the fan by hand and check for obstructions.

A final check will be required once the air supply has

been connected to the fan. A minimum of 90 PSI

(620 kPa) will be required to fully reverse the

blade pitch. Spin the fan by hand with the blade

pitch reversed and check for obstructions.

G.

Tighten the fan belts and replace all the fan guards

and safety equipment.

H.

Attach the “WARNING” label to the machine, on a

housing, guard, or any location near the fan where it

can be easily seen.