1.1

INTRODUCTION

This manual (

P/N 01553

) is produced to assist in the in-

stallation, operation and maintenance of Flexxaire

®

TAC1000-P and TAC1000-H Series Fan Systems.

Flexxaire has made every effort to ensure that the infor-

mation contained in this manual is correct and complete at

the time of printing. Flexxaire

®

will assume no responsibil-

ity for any errors or omissions. If you have any questions

regarding this manual or any other document provided with

your fan system, please contact:

Flexxaire

Product Support Department

10430-180 Street

Edmonton, Alberta, Canada

T5S-1C3

Phone: 780-483-3267

Fax: 780-483-6099

1.2

IMPORTANT SAFETY INFORMATION

The safety information in this publication is to be used in

conjunction with the safety information supplied from the

original machine manufacturer. Please refer to all safety

information supplied, prior to doing any work on the fan

assembly or any other component to assure safety.

Improper operation, maintenance or repair of this

product can be dangerous and could result in injury

or death.

Always use Flexxaire parts and components or Flexxaire

approved parts and components. The use of unapproved

parts and/or components may void the 1-year warranty.

Do not operate or perform any maintenance on this

product until you have read and understand the op-

eration and maintenance information. Please con-

tact Flexxaire or an approved dealer for any infor-

mation that you may require.

The person(s) servicing the product may be unfa-

miliar with many of the systems or components on

the product. This makes it important to use caution

when performing any type of service work. A

knowledge of the product and/or its components is

important before the removal or disassembly of any

component.

1.2.1

PROTECTIVE EQUIPMENT

Always wear protective glasses, protective shoes and any

other protective equipment as required by job conditions

when working around this product.

1.2.3

SPRING LOADED FAN HUB

The hub assembly is spring loaded. If disassembly of the

hub is required, take caution that you are well protected

from the hub’s release which may be sudden and pose an

impact related injury. Also make sure that the internal

pressure is released. Consult the pneumatic or hydraulic

control instructions.

1.2.3

HOT FLUIDS AND PARTS

To avoid burns, be alert for hot parts on the assembly or

the machine that have just been stopped and have hot flu-

id in lines, tubes and compartments.

1.3

PRODUCT SUPPORT

The Product Support Department provides technical sup-

port, information on fan installation and maintenance,

parts, instruction manuals, and is responsible for warranty

administration. Contact the Product Support Department

for any problems that this technical manual does not ad-

dress.

Phone: 780-483-3267

Monday to Friday 8:00 a.m to 4:00 p.m. MST

1.4

FAN SPECIFICATIONS

The following needs to be considered prior to the installa-

tion of the Flexxaire Fan System. If your situation is listed

in this section,

DO NOT INSTALL THE FAN.

Damage

and/or injury may occur.

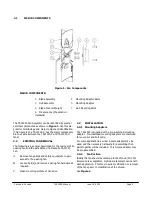

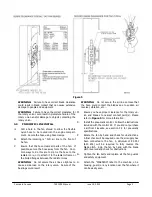

1.4.1 MOUNTING

WARNING:

This fan is not designed to be mounted onto

a crank shaft or crank shaft pulley. Torsional vibration

from crankshafts will damage the fan and could result in

machine damage and serious injury.

Printed in Canada

TAC1000 Manual

June 19, 2013

Page 1