16

U-Type

®

Secondary Cleaner

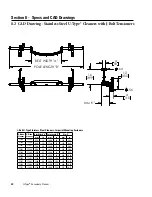

3. Install the new blade.

a.

Center the blade in the holder (Fig. 3).

b. Tighten all plate retaining screws.

c. Tighten blade retaining screws 8 turns and tighten the blade

retaining screw locknuts (Fig 3).

5. Inspect for full blade contact to the belt. Important - Always be

sure there is uniform contact between the blade and the belt. If the

blade is not in full contact with the belt at the edges and center, raise

or lower the pole position of the cleaner and reapply the tension (See

Installation Instructions).

Section 6 - Maintenance

2. Remove the worn blade.

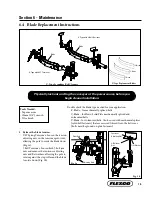

a. Loosen both locknuts on the blade retaining screws. Turn blade retaining screws out 8 turns (Fig. 2a).

b. Loosen or remove all plate retaining screws.

c. From one end, insert a screwdriver under the blade and lightly pry the blade up and out of the blade

holder (Fig. 2b). Once the blade breaks free, pull it out by hand.

c. Remove the blade from the holder and clean material buildup from holder with a wire brush (Fig. 2c).

Clean buildup

from blade holder

Loosen both

locknuts and blade

retaining screws

Insert

screwdriver,

pry blade up

Fig. 2a

Fig. 2b

Fig. 2c

Tighten both blade

retaining screws

and locknuts

Plate

retaining

screws

Center new blade

in blade holder

Fig. 3

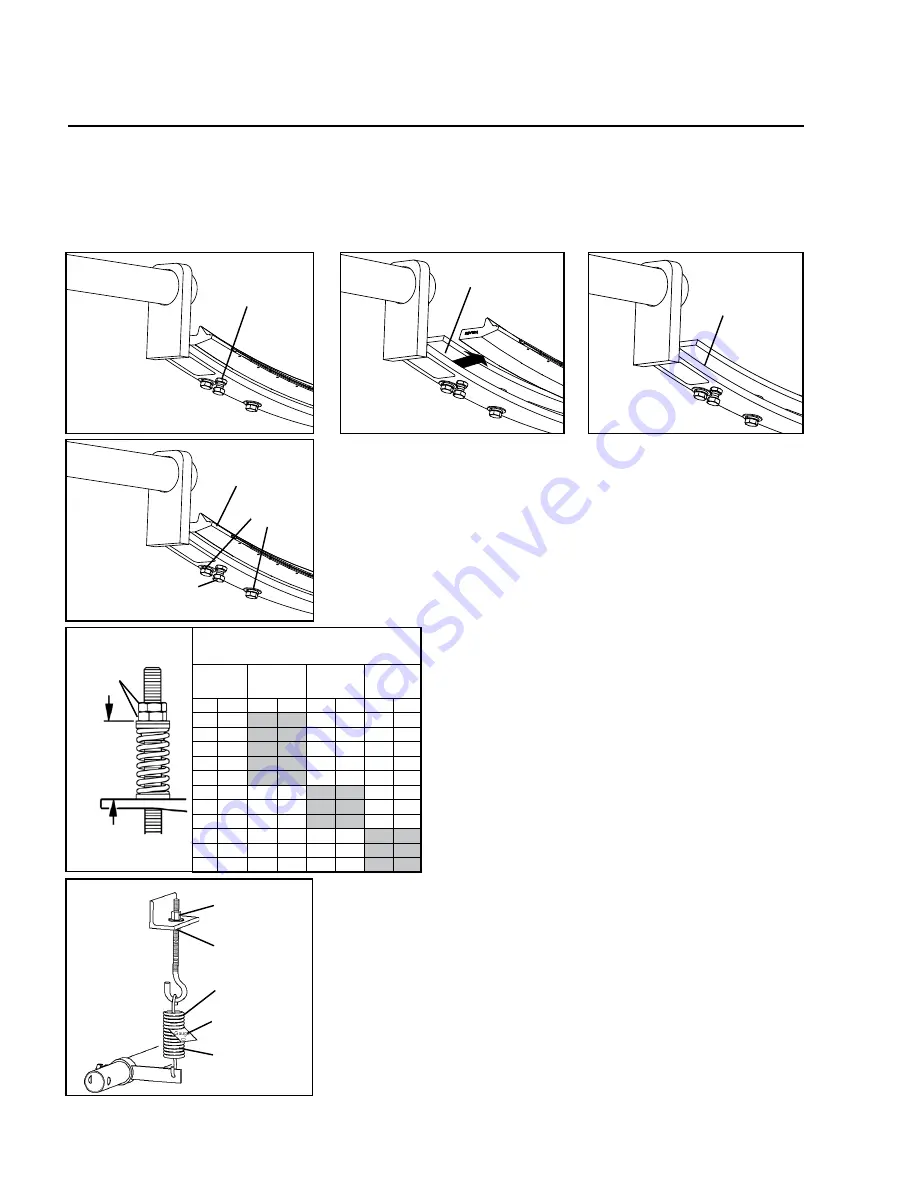

Tensioner

Adjusting Nut

J Bolt Jam Nut

Tension Spring

Clearance .030"

between coils

Fig. 4b

Spring Tension

Gauge

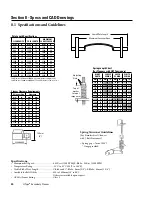

4. Reset the blade tension.

UST Spring Tensioner: Refer to the chart for the spring

length required for the belt width. Lightly pull the pivot

arm toward the end of the torque arm slot nearest the

pole and turn the adjusting nuts until the required

spring length is achieved (Fig. 4a). NOTE: The chart

is also on the cleaner’s pivot shaft bracket for future

reference for retensioning maintenance. Reference

Section 4 (Cleaner Installation Instructions) on page 6.

J-Bolt Tensioner: Rotate the pole and insert the J bolts

through the J bolt mount holes and install the flat

washers and tensioner adjusting nuts. Turn the tensioner

adjusting nuts until a .7mm (.030”) gap (use Spring

Tension Gauge included with cleaner) appears between

all coils of the tension spring (Fig. 4b). Lock both J bolt

jam nuts.

Test run the cleaner. Run the conveyor for at least 15 minutes and

inspect the cleaning performance. Check the spring length for proper

tensioning. Make adjustments as necessary.

Top of

washer

to top of

torque arm

Adjusting

Nuts

Spring Length Chart

(for Cleaners with UST Tensioners)

Blade

Width

Purple

Spring

Silver

Spring

White

Spring

mm

in.

mm

in.

mm

in.

mm

in.

450

18

154

6 1/8

160

6 3/8

162

6 3/8

600

24

148

5 7/8

148

6 1/4

160

6 1/4

750

30

140

5 1/2

156

6 1/8

158

6 1/4

900

36

136

5 3/8

152

6

156

6 1/8

1050

42

128

5

150

5 7/8

154

6 1/8

1200

48

N/A

N/A

146

5 3/4

152

6

1350

54

N/A

N/A

142

5 5/8

150

5 7/8

1500

60

N/A

N/A

140

5 1/2

150

5 7/8

1800

72

N/A

N/A

N/A

N/A

140

5 1/2

2100

84

N/A

N/A

N/A

N/A

136

5 3/8

2400

96

N/A

N/A

N/A

N/A

132

5 1/4

Fig. 4a