12

U-Type

®

Secondary Cleaner

Fig. 8J

Tensioner

Adjusting Nut

J-Bolt Jam Nut

Tension Spring

Clearance .030"

Between Coils

Spring Tension

Gauge

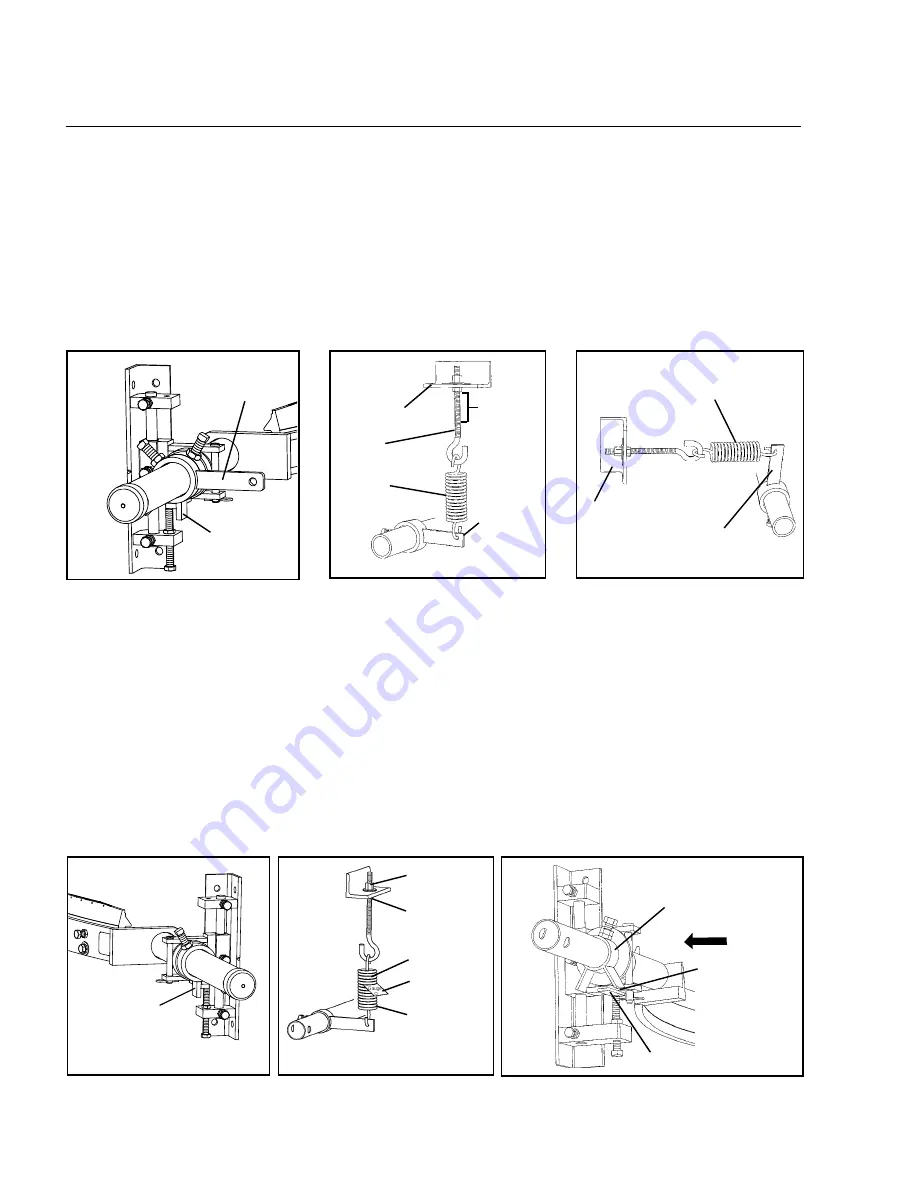

9J. Set the blade travel stop.

Set both stop collars to a clearance of 6mm (1/4”) for UV and UC cleaners, or 13mm (1/2”) for UF cleaners, from

bearing mount stops (Fig. 9J). This is to prevent blade from moving into belt. Tighten set screws and lock nuts.

7J. Set up stop collar and assemble opposite tensioning system.

a. Loosen stop collar (Fig. 7J).

b. Slide the second adjusting arm on pole end; assemble and mount tensioning system.

8J. Set the spring tension.

a. Loosen J-bolt jam nuts and turn tensioner adjusting nuts until both springs have a clearance of about

.030" between all coils (use Spring Tension Gauge included in installation instruction packet.) (Fig. 8J).

IMPORTANT: Always be sure there is uniform contact between blade and belt.

b. If blade is not in full contact with belt at edges and center, either raise or lower pole position of cleaner

and reapply tension.

Fig. 7J

Stop Collar

Clearance 6mm (1/4”)

for UV and UC;

13mm (1/2”) for UF

Fig. 9J

Bearing

Mount Stop

Stop Collar

Belt Direction

4.2 U-Type® SS J-Bolt Cleaner (cont.)

Section 4 - Installation Instructions

6J. Mount the tensioning system.

a. Slide one adjusting arm onto pole end with stop collar that was not tightened (Fig. 6Ja).

b. Assemble tension spring and J-bolt mount to adjusting arm. Locate position for J-bolt mount (Fig. 6Jb).

IMPORTANT: Allow at least 50mm (2”) of upward movement for J-bolt end for future adjustment.

c. The J-bolt mount can be mounted in any position (360 degrees) around pole. The only requirement is

that J-bolt and spring remain perpendicular to adjusting arm (Fig. 6Jc).

d. Weld or bolt J-bolt mount into position.

e. Tighten adjusting arm set screw and lock nut to secure position on pole.

f. Adjust J-bolt to apply light tension on tension spring.

Fig. 6Ja

Fig. 6Jc

J-Bolt Mount

Tension Spring

Adjusting Arm

Adjusting Arm

Fig. 6Jb

Tension

Spring

J-Bolt

J-Bolt Mount

(50mm (2”)

Upward

Movement

Adjusting Arm

Stop Collar