FL

AIR

MO ApS

–

Lundeborgvej 3

–

DK-9220 Aalborg

–

Denmark

Phone: +45 53717220 Web: www.flairmo.dk - E-mail: [email protected]

Important - read this first!

Please read the following information and operating instructions

included with this product before use. This information is for your safety

and it is important that you follow these instructions. It will also help

prevent damage to the product. Failure to operate the unit in

accordance with the instructions or using unauthorized spare parts can

cause damage to the unit and could cause serious injury.

CAUTION: To reduce risk of electric shock

• Only authorized service agents should carry out service. Removing

parts or attempting repairs can create an electric shock. Refer all

servicing to qualified service agents.

• If this unit is supplied with a three-pin plug, connect with a properly

earthed outlet only.

WARNING: To reduce risk of electrocution

• Do not use this unit with electrical voltages other than stated on the

rating plate.

• Always unplug this unit immediately after use, and store in a dry place

• Do not use this product in or near liquid or where it can fall or be

pulled into water or other liquids.

• Do not reach for this product if it has fallen into liquid Unplug

immediately.

• This unit is not weatherproof. Never operate outdoors in the rain or in

a wet area.

DANGER: To reduce risk of explosion or fire

• Do not use this product in or near explosive atmospheres or where

aerosol products are being used.

• Do not pump any other gases other than atmospheric air.

• Do not pump combustible liquids or vapours with this product.

• Do not use this unit near naked flames.

CAUTION: To prevent injury

• Compressed air can be dangerous; do not direct airflow at your body.

• Always keep the compressor out of reach of children.

• Never operate this product if it has a damaged power lead or plug, if

it has been dropped or damaged, or if it has fallen into water. Return

the product to a service centre for examination and repair.

• Keep the electrical cable away from heat.

• Never restrict fans. Ensure all openings are kept free of restriction.

• Never insert fingers or any other objects into fans.

• This unit is thermally protected and can automatically restart when

the overload resets.

• Wear safety glasses when servicing the compressor.

• Use only in well ventilated areas.

• Do not use any items not recommended for use with compressed air.

• The surface of the compressor can get hot. Do not touch compressor

motor during operation.

• Failure to observe the above safety precautions could result in severe

bodily injury, including death in extreme cases.

.

IMPORTANT: General directions for use

• Protect compressor against rain, moisture, frost and dust.

• The OF300 series is constructed and approved for a max. pressure

as indicated under Technical data

• Do not operate compressor at ambient temperatures exceeding

40°C/104°F or falling below 0°C/32°F.

• If the supply lead on the compressor is defective, an authorized

FLAIRMO distributor or other qualified personnel must carry out the

repair.

Warranty

Provided that the operational instructions have been carried out,

your FLAIRMO compressor is guaranteed against faulty material or

workmanship for 2 years.

The guarantee does not cover damage caused by violence, misuse,

incorrect repairs or use of unoriginal spare parts.

Costs of transportation of parts/equipment are not covered by the

guarantee.

In Scandinavia it is NL-92 Terms & Conditions that applies.

FLAIRMO ApS reserves the right to change technical

specifications/constructions.

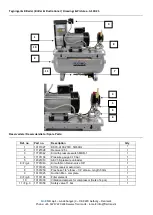

Contents of box (motor only)

Your new compressor/vacuum pump should be delivered in

a clean and undamaged box. If not, contact your distributor

immediately. The box should contain the following:

Installation (motor only)

Your FLAIRMO motor is very easy to operate. Observe the

following simple instructions and you will get many years’

service from your motor.

• Visually inspect unit for shipping damage, contact your

supplier immediately if you think the unit may have been

damaged.

Warning!

To avoid the risk of electric shock, do not install the

compressor in areas where it may get in contact with

water or other liquids. In which case protection is required.

• Remove the plastic protection from the outlets.

• Use only pressure pipes tolerating

a constant temperature of min. 1500C. Ensure that the

pressure pipes have a sufficient internal diameter to avoid

pressure loss in the system. Check for leaks.

• Mount the supplied feet on the compressor

• It is important that the compressor is mounted vertically to avoid

damage to the rubber feet. If the compressor is to be mounted in

another position, please contact FLAIRMO for further information.

• Sufficient cooling from the surroundings is important. Place the motor

in a dustfree, dry and cool, yet frostfree, room. Do not install in a closed

cupboard, unless adequate openings for ventilation are available on top

and bottom (minimum 500 cm²/77.5 in² each). If the motor is placed

under a table, a minimum of 10 cm/3 inch free height must be available

above the motor (fig. 3), or an opening of Ø30cm/11.8 inches,

corresponding to the top of the motor, may be cut in the table.

Ensure that the motor stands firmly on the floor.

• The intake air may be supplied from another place (for

instance outside).

Nipple and hose should then be mounted in the thread on the top of the

intake filter, and led to the external air source.

Ensure that hoses for the intake are sufficient to avoid

performance loss.

Electrical installation (motor only)

Warning!

Incorrect electrical connection may result in electric

shock. The electrical connection must be carried out

in accordance with local electrical regulations and by

qualified electrical engineers.

Note!

Earthing of all AC models must be ensured during

installation. The capacitor must be earthed, as failure to do

so may cause electric shock when touched. Plug the motor

into an earthed socket of nominal voltage and ensure that

fusing is adequate, see Technical Specifications

AC models

• For electrical connection, refer to page 7

• Check motor plate for frequency, voltage and capacitor and

ensure that it corresponds to the voltage and frequency

used for the motor. The voltage stated on the motor plate:

120/240V (/) means that the motor can operate at 120V or

240V, but this requires recoupling of the internal wiring from

the electrical motor (see the electrical diagrams). 220-230V

(-) means that the motor may operate within the range of

220V to 230V without recoupling of the internal wiring.

DC models

• For electrical connection, refer to page 7

• During installation of the DC motor, check the motor plate

for the direction of rotation as it is important that the "+" and

"-" poles are connected in a correct way (fig. 5). Otherwise,

Information

Please note that you can find the pictures and

figures we are referring to on page 6-9.