Lit. No. 43573/43583/43593, Rev. 01

8

August 15, 2013

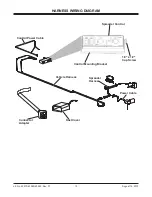

LOADING

DETERMINING VEHICLE PAYLOAD

1. Install the hopper spreader and optional

equipment according to the instructions.

2. Install or attach any other equipment that will be

on the vehicle while the hopper spreader will be in

use (step bumper, trailer hitch, snowplows, etc.).

Fill gas tanks.

3. Obtain the Gross Vehicle Weight Rating (GVWR),

Front Gross Axle Weight Rating (FGAWR) and

Rear Gross Axle Weight Rating (RGAWR) from

the certi

fi

cation label located inside the driver-side

door jamb or door.

4. With the occupants in the truck for normal hopper

spreader operation, weigh the vehicle to obtain

gross vehicle weight (GVW).

5. Subtract the GVW from the GVWR to determine

the available material payload.

6. Obtain the weight per cubic yard (lb/cu yd) of

the desired material. Divide the weight into the

payload to determine the maximum volume of

material that can be carried.

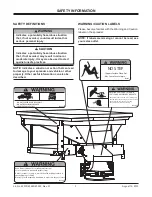

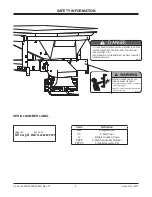

WARNING

Overloading could result in an accident or

damage. Do not exceed GVWR or GAWR

ratings as found on the driver-side door

cornerpost of the vehicle. See Loading

Section to determine maximum volumes of

spreading material.

7. Compare the maximum volume to determine the

maximum height of the material in the hopper

spreader.

8. Fill the hopper with the material to the calculated

height. Reweigh the vehicle with occupants

and verify the GVW, Front Gross Axle Weight

and Rear Gross Axle Weight are less than the

vehicle's ratings.

9. Repeat Steps 7 and 8 for each type of material.

Material

Density

(lb/ft

3

)

Rock Salt

– Dry

80–90

Sand/Salt Mix

– Dry

95–120

WARNING

Do not overload vehicle. Use chart below

to calculate weight of material. Weights of

material are an average for dry materials.

CAUTION

Never use wet materials or materials with

foreign debris with any of these spreaders.

These units are designed to handle dry, clean,

free

fl

owing material.

Содержание POLY-CASTER

Страница 2: ......