EH Valves (NPS 8 through 14)

Instruction Manual

April 2009

5

valve. Drain the process media from

both sides of the valve.

D

Vent the power actuator loading

pressure and relieve any actuator

spring precompression.

D

Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D

The valve packing box may

contain process fluids that are

pressurized,

even when the valve has

been removed from the pipeline.

Process fluids may spray out under

pressure when removing the packing

hardware or packing rings, or when

loosening the packing box pipe plug.

D

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

WARNING

Refer to table 4 for valve assembly

weights and the appropriate actuator

instruction manual for actuator

assembly weights. Due to the size and

weight of the valve and actuator

assembly, be sure adequately sized

hoists and chains or slings are used to

handle it. Also, take proper

precautions to prevent personnel from

being injured if the hoist or rigging

slips unexpectedly.

Note

Whenever a gasket seal is disturbed

by removing or shifting gasketed

parts, install a new gasket upon

reassembly. This is necessary to

ensure a good gasket seal.

8. After all maintenance is complete, refer to the

Trim Replacement procedure to assemble the valve

body.

Note

If the valve has ENVIRO-SEAL

r

live-loaded packing installed, see the

Fisher instruction manual titled

ENVIRO-SEAL Packing System for

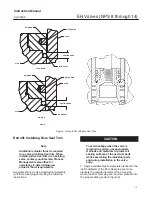

Figure 2. Lubricator and Lubricator/Isolating Valve

LUBRICATOR

LUBRICATOR/ISOLATING VALVE

10A9421-A

AJ5428-D

A0832-2/IL

14

14

27

Sliding-Stem Valves for packing

instructions.

If the valve has HIGH-SEAL live-loaded

packing installed, see the Fisher

instruction manual titled HIGH-SEAL

Live-Loaded Packing System for

instructions.

Packing Lubrication

WARNING

To avoid personal injury or property

damage resulting from fire or

explosion, do not lubricate packing

used in oxygen service or in

processes with temperatures over

260

_

C (500

_

F).

Note

ENVIRO-SEAL or HIGH-SEAL packing

does not require lubrication.

A lubricator or lubricator/isolating valve (figure 2) is

recommended for PTFE-impregnated composition

packing. The lubricator or lubricator/isolating valve is

installed in place of the pipe plug in the bonnet. Use

a good quality silicon-base lubricant. Do not lubricate

packing used in oxygen service or in processes with

temperatures over 260

_

C (500

_

F). To operate the

lubricator, turn the cap screw clockwise to force

lubricant into the packing box. The