EH Valves (NPS 8 through 14)

Instruction Manual

April 2009

10

Table 7. Seat Ring and Seat Ring Cap Screw Lubricants and Recommended Torque for Seat Ring Cap Screws

LUBRICANT

VALVE

SIZE,

NPS

VALVE

RATING

RECOMMENDED TORQUE

Spiral Wound

Gasket Construction

O-Ring Construction or

Constructions for

Sour Gas Service

N

S

m

lbf

S

ft

N

S

m

lbf

S

ft

Lithium Grease or

Anti-Seize

Lubricant

8, 10

CL1500

61

45

41

30

CL2500

95

70

61

45

12, 14

CL1500

95

70

61

45

CL2500

95

70

61

45

Dry Film

Lubricant

8, 10

CL1500

47

35

34

25

CL2500

75

55

47

35

12, 14

CL1500

75

55

47

35

CL2500

75

55

47

35

16. Mount the actuator on the valve body assembly,

and reconnect the actuator and valve plug stem

according to the Actuator Mounting procedure. After

the control valve is returned to service, retighten the

hex nuts (key 14, figure 12 or 13) to the torque

recommended in table 6.

Trim Removal

WARNING

Refer to the WARNING at the

beginning of the Maintenance section

in this instruction manual.

For Bore seal construction, see the appropriate Bore

seal sections in this instruction manual.

Key numbers referenced in this procedure are

shown in figure 12 for the EHD valve and figure 13

for the EHT valve except where indicated.

1. Remove the actuator and bonnet by following

steps 1 through 9 of the Replacing Packing

procedure.

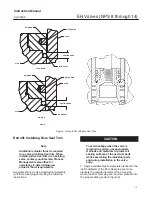

2. To remove the seat ring (key 6), remove the cap

screws (key 7). Install eyebolts or similar devices in

the 5/8 inch 11-UNC tapped holes (9/16 inch

12-UNC for an NPS 8 or 10 CL1500 valve). Use the

eyebolts to carefully lift the seat ring out of the valve

body. If the seat ring is to be reused, exercise care

to protect the gasket surfaces on the bottom of the

seat ring.

3. Remove the spiral wound seat ring gasket or

O-ring (key 12).

4. Refer to the following appropriate valve plug

maintenance procedure or to the Lapping Seats

procedure.

EHD and EHT Valve Plug Maintenance

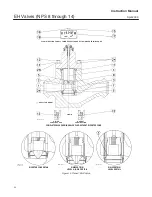

Key numbers used in this procedure are shown in

figure 12 for the EHD valve and in figure 13 for the

EHT valve.

1. With the valve plug (key 3) removed per the Trim

Removal procedure, proceed as appropriate:

For the EHD valve,

the piston rings (key 8) are each

in two sections; remove the sections from the

grooves in the valve plug.

For all EHT valves,

work the retaining ring (key 10)

off the valve plug with a screwdriver. Carefully slide

the backup ring and seal ring (keys 9 and 8) off the

valve plug. Additionally, for the EHT valve with

Whisper Trim Level D cage, remove the two sections

of the piston ring (key 30, figure 13).

2. To replace the valve plug stem (key 4), drive out

the pin (key 5) and unscrew the stem from the valve

plug (key 3).

CAUTION

Never reuse an old stem with a new

valve plug. Using an old stem with a

new plug requires drilling a new pin

hole in the stem. This weakens the

stem and may cause the stem to fail in

service. If a new valve plug is required,

always order a valve plug, stem, and

pin as an assembly. Specify the

correct part number of each of the

three parts but state that the parts are

being ordered as an assembly.

A used valve plug may be reused with

a new stem.

3. Thread the new stem into the valve plug until the

stem wedges tightly at the end of the thread. Using