Lit. No. 49599, Rev. 05

8

April 1, 2018

29250, 29350, 97000, 97000-1, 97100, 97100-1

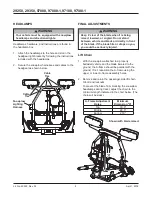

HEADLAMPS

Headlamps, hardware, and instructions are found in

the headlamp box.

1. Attach the headlamps to the hole and slot in the

headgear light bracket by following the instructions

included with the headlamps.

2. Secure the snowplow harnesses and cables to the

headgear as shown below.

WARNING

Your vehicle must be equipped with snowplow

headlamps and directional lights.

Cable

Ties

Cable

Ties

Snowplow

Lighting

Harness

FINAL ADJUSTMENTS

Lift Chain

1. With the snowplow attached to a properly

ballasted vehicle and the blade lowered to the

ground, the A-frame should be parallel with the

ground. If not, reposition the A-frame using the

upper or lower A-frame assembly holes.

2. Remove and retain the passenger-side lift chain

U-bolt and locknuts.

To prevent the blade from blocking the snowplow

headlamps during travel, adjust the chain to the

minimum length indicated in the chart below. (The

chain will be slack.)

A-Frame Adjustment

Holes

Minimum

Dimension "A"

Top

30.0"

Middle

28.5"

Bottom

27.0"

"A"

Shown with blade raised.

WARNING

Keep 8' clear of the blade when it is being

raised, lowered, or angled. Do not stand

between vehicle and blade or directly in front

of the blade. If the blade hits or drops on you,

you could be seriously injured.