249W Level Sensor

Instruction Manual

Form 5729

May 2006

10

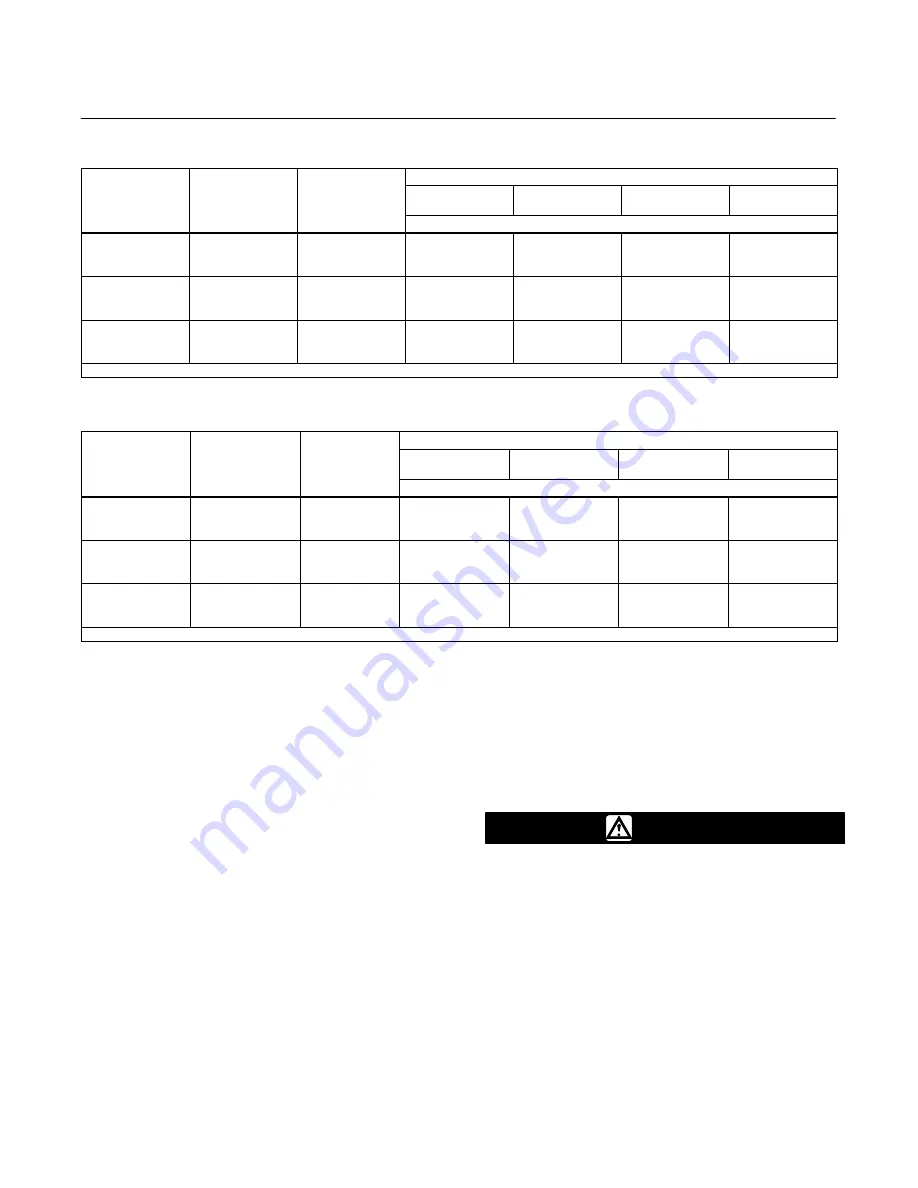

Table 2. Recommended Bolt Torque for Typical Lubricants (3-Inch Flanges)

Bolt and Nut

Material

Bolt Size

Mating Flange

Class

Lubricant

Fisher NCF2

(1)

Coating

Molykote

R

321R

Lubriplate

R

Mag-1

Never-Seez

R

Nickel Special

Torque, N

S

m (lbf

S

ft)

SA193-B7

5/8 - 11

3/4 - 10

3/4 - 10

CL150

CL300

CL600

431

±

62 (97

±

14)

667

±

98 (150

±

22)

667

±

98 (150

±

22)

431

±

62 (97

±

14)

667

±

98 (150

±

22)

667

±

98 (150

±

22)

556

±

84 (125

±

19)

845

±

124 (190

±

28)

845

±

124 (190

±

28)

534

±

80 (120

±

18)

801

±

133 (180

±

30)

801

±

133 (180

±

30)

SA193-B7M

5/8 - 11

3/4 - 10

3/4 - 10

CL150

CL300

CL600

431

±

44 (97

±

10)

689

±

71 (155

±

16)

689

±

71 (155

±

16)

431

±

44 (97

±

10)

689

±

71 (155

±

16)

689

±

71 (155

±

16)

556

±

58 (125

±

13)

890

±

89 (200

±

20)

890

±

89 (200

±

20)

534

±

53 (120

±

12

845

±

84 (190

±

19)

845

±

84 (190

±

19)

SA193-B8M CL2

5/8 - 11

3/4 - 10

3/4 - 10

CL150

CL300

CL600

Not applicable

418

±

62 (94

±

14)

689

±

102 (155

±

23)

689

±

102 (155

±

23)

534

±

80 (120

±

18)

890

±

133 (200

±

30)

890

±

133 (200

±

30)

511

±

67 (115

±

15)

845

±

124 (190

±

28)

845

±

124 (190

±

28)

1. Torque values for NCF2 without additional lubricant are equal to Molykote 321R

Table 3. Recommended Bolt Torque for Typical Lubricants (4-Inch Flanges)

Bolt and Nut

Material

Bolt Size

Mating Flange

Class

Lubricant

Fisher NCF2

(1)

Coating

Molykote 321R

Lubriplate Mag-1

Never-Seez

Nickel Special

Torque, N

S

m (lbf

S

ft)

SA193-B7

5/8 - 11

3/4 - 10

7/8 - 9

CL150

CL300

CL600

431

±

62 (97

±

14)

667

±

98 (150

±

22)

1022

±

102 (230

±

23)

431

±

62 (97

±

14)

667

±

98 (150

±

22)

1022

±

102 (230

±

23)

556

±

84 (125

±

19)

845

±

124 (190

±

28)

1289

±

129 (290

±

29)

534

±

80 (120

±

18)

801

±

133 (180

±

30)

1222

±

122 (275

±

28)

SA193-B7M

5/8 - 11

3/4 - 10

7/8 - 9

CL150

CL300

CL600

431

±

44 (97

±

10)

689

±

71 (155

±

16)

1022

±

102 (230

±

23)

431

±

44 (97

±

10)

689

±

71 (155

±

16)

1022

±

102 (230

±

23)

556

±

58 (125

±

13)

890

±

89 (200

±

20)

1289

±

129 (290

±

29)

534

±

53 (120

±

12

845

±

84 (190

±

19)

1222

±

122 (275

±

28)

SA193-B8M CL2

5/8 - 11

3/4 - 10

7/8 - 9

CL150

CL300

CL600

Not applicable

418

±

62 (94

±

14)

689

±

102 (155

±

23)

956

±

96 (255

±

96)

534

±

80 (120

±

18)

890

±

133 (200

±

30)

1133

±

114 (255

±

26)

511

±

67 (115

±

15)

845

±

124 (190

±

28)

1111

±

111 (250

±

25)

1. Torque values for NCF2 without additional lubricant are equal to Molykote 321R

Note

In the next step, if mounting the wafer

body on a displacer cage and a flange

adaptor is required, install the flange

adaptor instead of the blind flange.

5. Refer to figure 11. Place a second seal on top of

the wafer body. Place a blind flange on the wafer

body so that the holes in the blind flange align with

the holes in the connecting flange.

6. Refer to figure 12. Secure the wafer body

between the blind flange and connecting flange by

inserting the remaining studs and nuts. Tighten the

nuts just enough to hold the wafer body in place.

7. Remove the nut from the stud that was used in

step 2. Reinsert the stud so it passes through the

holes in the blind flange and connecting flange.

Thread the nut back onto the stud.

8. Tighten all nuts in a crisscross fashion to the

torque recommended in tables 2 or 3.

Maintenance

Sensor parts are subject to normal wear and must

be inspected and replaced as necessary. The

frequency of inspection and replacement depends

upon the severity of service conditions.

WARNING

Avoid personal injury or property

damage resulting from the sudden

release of pressure. Before performing

any maintenance procedure:

D

Always wear protective clothing,

gloves, and eyewear.

D

Relieve any process pressure in

the process vessel where the Type

249W sensor is installed.

D

Drain the process liquid from the

process vessel.