DFLEX Assembly instructions |

26

-

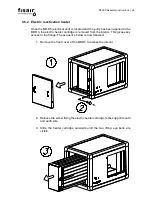

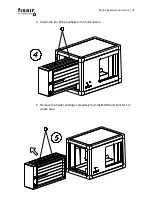

After removing the heater cartridge, the MOD5 (electric unit) has to be lifted and

placed on top of the MOD3 (process fan). It must be positioned in line with the

MOD4 (basic unit) and centered with the S5-4 reactivation duct shaft:

1. The MOD5 is lifted by suspending it from the 4 lugs located on the ends.

2. Move the MOD5 to the indicated position.

S5-4

Содержание DFLEX 1100

Страница 2: ...DFLEX Assembly instructions 2...

Страница 16: ...DFLEX Assembly instructions 16 The following result is obtained...

Страница 29: ...DFLEX Assembly instructions 29 DFLEX 1100 400V 5...

Страница 30: ...DFLEX Assembly instructions 30 DFLEX 1100 440 480V NOT WIRING...

Страница 31: ...DFLEX Assembly instructions 31 DFLEX 1300 400V 5...

Страница 32: ...DFLEX Assembly instructions 32 DFLEX 1300 460V 5 NOT WIRING...

Страница 33: ...DFLEX Assembly instructions 33 DFLEX 1700 400V 5...

Страница 34: ...DFLEX Assembly instructions 34 DFLEX 2100 400V 5...

Страница 35: ...DFLEX Assembly instructions 35 DFLEX 2100 460V 5 48 Elementos NOT WIRING...

Страница 36: ...DFLEX Assembly instructions 36 DFLEX 2100 460V 5 45 elements Requires SSR in E4 NOT WIRING...

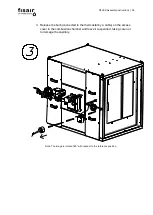

Страница 37: ...DFLEX Assembly instructions 37 8 Finally replace and close the front cover of the MOD5 electrical unit...

Страница 49: ...DFLEX Assembly instructions 49 Finally the different cable connections should be as shown below...