5

STEP 1:

If filter media is already in the media tank, proceed to step 3. If media is shipped

separately, remove the fill port cap by turning it counter-clockwise with the wrench

provided. After fill port cap is removed also remove the filter screen inside the fill port.

Add media through the fill port using a funnel. Do not overfill the tank. At least 18" of

freeboard (empty space) is required at the top of the media tank. More media may have

been provided than required for initial fill. Save any extra media for future replenishment.

Clean any media out of fill port threads. Do not replace the fill port cap yet.

STEP 2:

Place carbon tank (tank with carbon and fill port) on the

LEFT

side with the inlet and

outlet pointing right. Place the softener tank on the

RIGHT

side with inlet and outlet

pointing left. Attach the control valve assembly to the front inlet/outlet openings of the

filter and softener tanks. Attach straight pipe adapter to back inlet/outlet openings of the

two tanks. Hand tighten union nuts. Do not over tighten.

STEP 3:

Use clips and screws provided and attach bypass valve to the inlet/outlet of the control

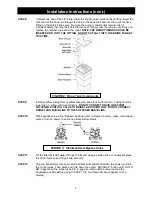

valve. See figure 1 below.

STEP 4:

Place unit at desired installation position.

DO NOT plug into electrical outlet at this

time (see STEP 12 on page 6). DO NOT put salt in the brine tank at this time (see

STEP 16 on page 7).

STEP 5:

Shut off water at main supply. Relieve pressure by opening nearest faucet. On private

well systems, turn off power to pump and drain pressure tank.

SHUT OFF POWER OR

FUEL SUPPLY TO WATER HEATER

.

STEP 6:

Cut main supply line as required

to fit plumbing to inlet and outlet of bypass valve.

DO

NOT PLUMB INLET AND OUTLET BACKWARDS

. Piping should be supported. Do not

apply heat to any fitting attached to the bypass or control valve.

STEP 7:

Use polyethylene drain line tubing provided (

NO VINYL TUBING

) to run drain line from

control valve discharge fitting to floor drain or sump pit capable of handling the backwash

rate of the unit.

DISCHARGE END OF THE DRAIN LINE MUST BE FIRMLY SECURED!

There must be an air gap at the end of the drain line to prevent siphoning of waste water

and meet plumbing code.

Total length of drain line should be 15’ or less. AVOID

OVERHEAD DRAINS

.

Installation Instructions

FIGURE 1: Top View of Control Valve

OUT

RETAINER CLIPS

DRAIN ELBOW

ELBOW LOCKNG CLIP

CONTROL VALVE

METER MODULE

BYPASS

IN SERVICE

POSITION

IN

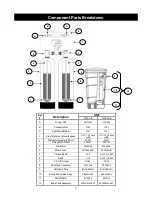

Содержание CITY Series

Страница 12: ...12 CITY Series Control Valve Breakdown ...