6

NFOD42 Gas Fireplace

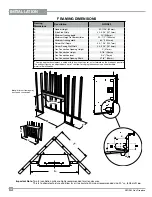

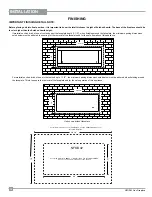

INSTALLATION

,03257$170(66$*(

6$9(7+(6(

,16758&7,216

The NFOD42 Gas Fireplace must be installed in

accordance with these instructions. Carefully read

all the instructions in this manual first. Consult the

"authority having jurisdiction" to determine the need

for a permit prior to starting the installation. It is the

responsibility of the installer to ensure this fireplace

is installed in compliance with manufacturers

instructions and all applicable codes.

%()25(<2867$57

Safe installation and operation of this appliance

requires common sense, however, we are required

by the Canadian Safety Standards and ANSI

Standards to make you aware of the following:

*(1(5$/6$)(7<

,1)250$7,21

The installation must conform with local

codes or, in the absence of local codes, with

%#0%5#$

, Natural Gas and Propane

Installation Code or

%#0%5#$

, Propane

installation code the Natural Gas Fuel Code,

#05+<0(2#

.

The appliance when installed, must be

electrically grounded in accordance with local

codes, or in the absence of local codes with the

Canadian Electrical Code CSA C22.1or with

the National Electrical Code, ANSI/NFPA 70.

See general construction and assembly

instructions. The appliance should be enclosed.

Inspect the burner before each use of the

appliance for blockage and any signs of

deterioration.

CHILDREN AND ADULTS SHOULD

BE ALERTED TO THE HAZARDS OF

HIGH SURFACE TEMPERATURES,

ESPECIALLY THE FIREPLACE GLASS

AND FACEPLATE, AND SHOULD STAY

AWAY TO AVOID BURNS OR CLOTHING

IGNITION.

THIS APPLIANCE SHALL BE USED

ONLY OUTDOORS IN A WELL-VENTI-

LATED SPACE AND SHALL NOT BE

USED IN A BUILDING, GARAGE OR ANY

OTHER ENCLOSED AREA.

INSTALLATION AND REPAIR SHOULD

BE DONE BY AN AUTHORIZED

SERVICE PERSON. THE APPLIANCE

SHOULD BE INSPECTED BEFORE

USE AND AT LEAST ANNUALLY BY A

PROFESSIONAL SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TO EXCESSIVE

LINT FROM CARPETING, BEDDING

MATERIAL, ETC. IT IS IMPERATIVE THAT

CONTROL COMPARTMENTS, BURNERS

AND CIRCULATING AIR PASSAGEWAYS

OF THE APPLIANCE BE KEPT CLEAN.

ANY GUARD OR OTHER PROTECTIVE

DEVICE REMOVED FOR SERVICING

THE APPLIANCE MUST BE REPLACED

PRIOR TO OPERATING THE APPLIANCE

WARNING: FAILURE TO INSTALL THIS

APPLIANCE CORRECTLY WILL VOID

YOUR WARRANTY AND MAY CAUSE A

SERIOUS FIRE.

CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED

ON OR NEAR THE APPLIANCE.

DO NOT USE THIS APPLIANCE IF

ANY PART HAS BEEN UNDER WATER.

IMMEDIATELY CALL A QUALIFIED

SERVICE TECHNICIAN TO INSPECT

THE APPLIANCE AND TO REPLACE

ANY PART OF THE CONTROL SYSTEM

AND ANY GAS CONTROL WHICH HAS

BEEN UNDER WATER.

YOUNG CHILDREN SHOULD BE CARE-

FULLY SUPERVISED WHEN THEY ARE

IN THE SAME AREA AS THE APPLI-

ANCE. TODDLERS, YOUNG CHILDREN

AND OTHERS MAY BE SUSCEPTIBLE

TO ACCIDENTAL CONTACT BURNS. A

PHYSICAL BARRIERS IS RECOMMEND-

ED IF THERE ARE AT RISK INDIVIDUAL

IN THE HOUSE. TO RESTRICT ACCESS

TO A FIREPLACE OR STOVE, INSTALL

AN ADJUSTABLE SAFETY GATE TO

KEEP TODDLERS, YOUNG CHILDREN

AND OTHER AT RISK INDIVIDUALS OUT

OF THE ROOM AND AWAY FROM HOT

SURFACES.

To prevent injury, do not allow anyone who is

unfamiliar with the operation to use the fireplace.

Wear gloves and safety glasses for protection

while doing required maintenance.

7)

Maximum gas inlet pressure = 1/2 psig.

Under no circumstances should this appliance

be modified. Parts that have to be removed for

servicing should be replaced prior to operating

this appliance.

Installation and any repairs to this appliance

should be done by a qualified service person.

A professional service person should be called

to inspect this appliance annually. Make it a

practice to have all of your gas appliances

checked annually.

Under no circumstances should any solid fuels

(wood, paper, cardboard, coal, etc.) be used in

this appliance.

11)

The appliance and its individual shutoff valve

must be disconnected from the gas supply

piping system during any pressure testing of

that system at test pressures in excess of 1/2

psi (3.5kPa).

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

The appliance area must be kept clear and

free of combustible materials, (gases and other

flammable vapours and liquids).

,WLVKLJKO\UHFRPPHQGHGWRSURWHFWWKH

LQWHULRUIURPPRLVWXUHUDLQVQRZ&RYHU

WKHHQFORVXUHRSHQLQJZKHQQRWLQXVH7KLV

¿UHSODFHLVRQO\IRUXVHZLWKWKHW\SHRIJDV

LQGLFDWHGRQWKHUDWLQJSODWH7KLV¿UHSODFH

LVQRWFRQYHUWLEOHIRUXVHZLWKRWKHUJDVHV

XQOHVVDFHUWL¿HGNLWLVXVHG

Cover

PXVW

be removed when burner is in

operation.

14)

When not using appliance for extended periods

of time - turn off gas supply.

Emissions from burning wood or gas could

contain chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

Содержание NFOD42 Series

Страница 40: ...40 NFOD42 Gas Fireplace NOTES ...

Страница 41: ...41 NFOD42 Gas Fireplace NOTES ...

Страница 42: ...42 NFOD42 Gas Fireplace NOTES ...