HOW TO UNPACK THE MACHINE

The machine is shipped in specific packaging. To remove it, proceed as follows:

1.

Place the lower part of the outer packaging in contact with the floor.

N.B.:

use the pictograms printed on the box as a reference.

2. Remove the outer package.

WARNING:

the machine is contained in specific packaging materials, whose elements (plastic bags, staples, etc.) can pose potential

hazards, and must not be left within reach of children, disabled persons, etc.

3. Remove the boxes containing the disc brushes and squeegee body from the machine.

WARNING:

It is recommended to wear the appropriate PPE (Personal Protective Equipment), suitable for the work to be carried out.

4. Insert a ramp in the rear part of the machine.

ATTENTION:

the ramp gradient must not be such as to cause damage to the machine as it comes down.

1.

The machine is fixed to the pallet with wedges (1) that block the wheels (

Fig.1

). Remove these wedges.

2. Check to make sure that the main switch on the control panel has been set to its “0” position. If this is not the case, turn the key (2) a quarter

turn to the left (

Fig.2

). Remove the key from the main switch.

3. Move to the left hand side of the machine and open the left lateral carter (3) (

Fig.3

).

4. Connect the power supply cable to the connector (4) that is located on the traction motor (

Fig.4

).

ATTENTION:

you are advised to have the electric connections completed by a qualified, FIMAP trained technician.

5. Once the electrical connection is complete, close the left-hand side carter again.

6. Grip the handle (5) and raise the recovery tank to the maintenance position (

Fig.5

).

7. Connect the backup battery carriage's connector to the machine's main system connector (

Fig.6

).

WARNING:

the following operations must be carried out by qualified personnel. An incorrect connection of the connector may cause a

malfunction of the device.

8. Grip the handle (5) and lower the recovery tank to its working position.

9. Sit on the driver’s seat.

10. Insert the key (2) into the main switch on the control panel. Set the main machine switch to its "I" position, by turning the key a quarter turn

to the right (

Fig.7)

).

11. Turn the brush head control lever (6) anti-clockwise (

Fig.8

); in this way the brush head body will be raised off the pallet.

12. Turn the squeegee control lever (7) clockwise (

Fig.9

) to raise the squeegee body off the pallet.

13. Engage the reverse gear using the reverse gear activation/deactivation lever (8) (

Fig.10

).

14. Press the drive pedal (9) (

Fig.11

) to begin moving the machine.

15. Drive the machine down the ramp.

ATTENTION:

during this operation, check there are no people or objects near the machine.

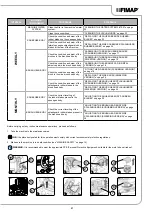

16. Bring the main switch to the "0" position by turning the key (21) a quarter turn anti-clockwise (

Fig.2

). Remove the key from the main switch.

17.

Get off the machine.

18. Grip the handle (5) and raise the recovery tank to the maintenance position (

Fig.5

).

19. Disconnect the backup battery carriage's connector from the machine's main system connector (

Fig.6

).

WARNING:

the following operations must be carried out by qualified personnel. An incorrect connection of the connector may cause a

malfunction of the device.

20. Grip the handle (5) and lower the recovery tank to its working position.

HANDLING THE PACKAGED MACHINE

The overall dimensions of the entire package are: height=1420mm width=1025mm length=1760mm, while the overall mass of the package is

300Kg.

N.B.:

it is recommended that all the packaging components be kept for any future machine transportation.

DANGER:

Move the packaged product with handling equipment that complies with legal requirements regarding size and mass of the

packaging.

13