4) Best performances from your Sabre Slasher will be gained when the P.T.O

revolutions are maintained between 540 and 650 r.p.m.

5) Always ensure that the front of skids are in contact with the ground. Failure to do

this will cause poor cut quality.

When fitting blades, special care should be taken to ensure that the genuine attaching

bolt is done up tight. Blades should now be free swinging on the special hardened

bush which is locked tight with the bolt.

Routine Servicing - IMPORTANT!

Like all machinery and motorcars, your

FIELDMASTER

must be routinely serviced

and checked as follows:

After the first 10 - 15 hours of use: check all gearbox mounting bolts.

3pt linkage

bolts, skid

,

roller or wheel mounting bolts, check flail and cutter bolts are tight. These

will tend to “bed in” after the first 10 - 15 hours and must be checked. Check all oil

levels, driveshaft grease, universal joints, roller and wheel bearings. Check main

hub

(holding flail/blade carrier to gearbox) is tightened as this is a taper spline shaft

that

also takes some “bedding-in” and must be tightened.

At the end of the mowing season: we request that you call your Fieldmaster agent to

have an “out of season service”. This will repeat all of the above service checks along

with replacement of blade tips, blade sharpening, balance check, check and or replace

any worn roller bearings, wheel bearings and ensure the machine is running correctly

ready for the next season. FAILURE TO ATTEND TO SERVICING AS SHOWN

ABOVE WILL ONLY CAUSE PREMATURE FAILURE OF SOME COMPONENTS.

THIS TYPE OF FAILURE IS NOT COVERED BY WARRANTY.

REMEMBER!

USE OF NON GENUINE FIELDMASTER PARTS

WILL INVALIDATE WARRANTY!!

We reserve the right to change or alter specifications without notification.

Содержание SABRE 1200

Страница 1: ...SABRE 1200 1500 ROTARY SLASHER TOPPER Models SABRE OWNERS OPERATORS MANUAL AND SPARE PARTS LIST ...

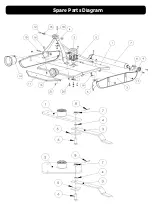

Страница 17: ...Spare Parts Diagram ...

Страница 20: ......

Страница 21: ......