13

Processed material

Working procedure

Electronics

setting

Rustic texture

on wood (LD 85)

3 - 5

Brushing

wood (KB 80)

2 - 3

Brushing

stained parts (BG 85)

2 - 3

Constant speed

The preselected motor speed remains con-

stant through electronic control. This en-

sures a uniform cutting speed even when

under load.

Overload safety device

In extreme applications, the current con-

sumption may far exceed the permitted

nominal value. A "safety coupling" integrated

in an electronic overload safety device

switches off the motor and prevents it from

burning out. Motor operation resumes im-

mediately after the load is relieved.

Temperature cut-out

To protect against overheating (burning out

of motor), an electronic temperature moni-

toring system has been installed. Prior to

reaching a critical motor temperature, the

safety electronics switches off the motor.

After a cooling time of approx. 3-5 minutes,

the machine can be operated again at full

load. The machine requires less time to cool

down when idling.

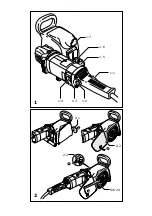

LED indicator

The rotary sander is

fi

tted with an electronic

adjusting wheel and a green and red LED [1-

3]. A green lit LED indicates that the rotary

sander is operating in normal mode. A red

lit LED indicates that the motor is operating

at approx. 70% overload. The overload or

temperature cut-out switches off the motor

if overloaded for longer periods.

However, alternately

fl

ashing green and red

LEDs indicate that the brushes are com-

pletely worn (remaining working hours max.

10 hours). In this case, have an authorised

after-sales service workshop replace the

carbon brushes the next day. Always replace

these brushes with special carbon brushes

available in pairs otherwise the LED indica-

tors will not work.

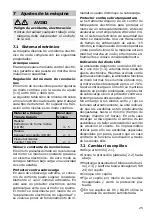

7.2 Changing the brushes

Loosen the screw [2-1].

Swivel the silver cover [2-2] down.

Press and hold the spindle lock [2-3] and

unscrew the hexagon nut (size 24) on the

brush.

Insert a different brush.

Tighten the hexagon nut to secure the

brush and then close the silver cover.

For brushes LD 85 and BG 85, use the

accompanying centring disc.

7.3 Adjusting the texture depth

Set the required texture depth using the

thumbwheel [1-6].

7.4 Dust extraction

CAUTION

Breathing in dust damages the

respiratory passage.

Always connect the machine to a dust

extractor.

When performing work that generates

dust, always wear a dust mask.

f

f

You can connect a Festool extractor to the

extractor connector [1-7]. The extractor

hose in the Festool extractor is 27 mm in

diameter.

8

Working with the ma-

chine

The RUSTOFIX gives beams or wooden pan-

elling a rustic texture.

Working method

After the

fi

rst working procedure with the

wire brush LD 85, protruding

fi

bres give the

wooden surface a rough feel. In the second

working procedure, plastic bristles KD 80

sand the textured surface to lend a smooth

fi

nish.

f

Always guide the machine evenly and in

the direction of the grain.

f

Hold the machine with both hands to en-

sure safe guidance.

f

Do not overload the machine by pressing

with excessive force! The best results are

achieved with moderate application pres-

sure.

f

f

f

f

f

L

f

Содержание RAS 180.03 E-HR

Страница 2: ......

Страница 3: ...1 2 1 4 2 1 2 2 2 3 SW 24 1 3 1 2 1 1 1 5 1 6 1 7 1 2 3 4...

Страница 67: ...67 Festool...

Страница 68: ...68 5 3 EN 60745 84 95 A K 4 3 2 f 6 Festool 120 60 1 1...

Страница 69: ...69 1 2 7 f 7 1 1 4 800 4000 LD 85 3 5 KB 80 2 3 BG 85 2 3 3 5 1 3 70 10...