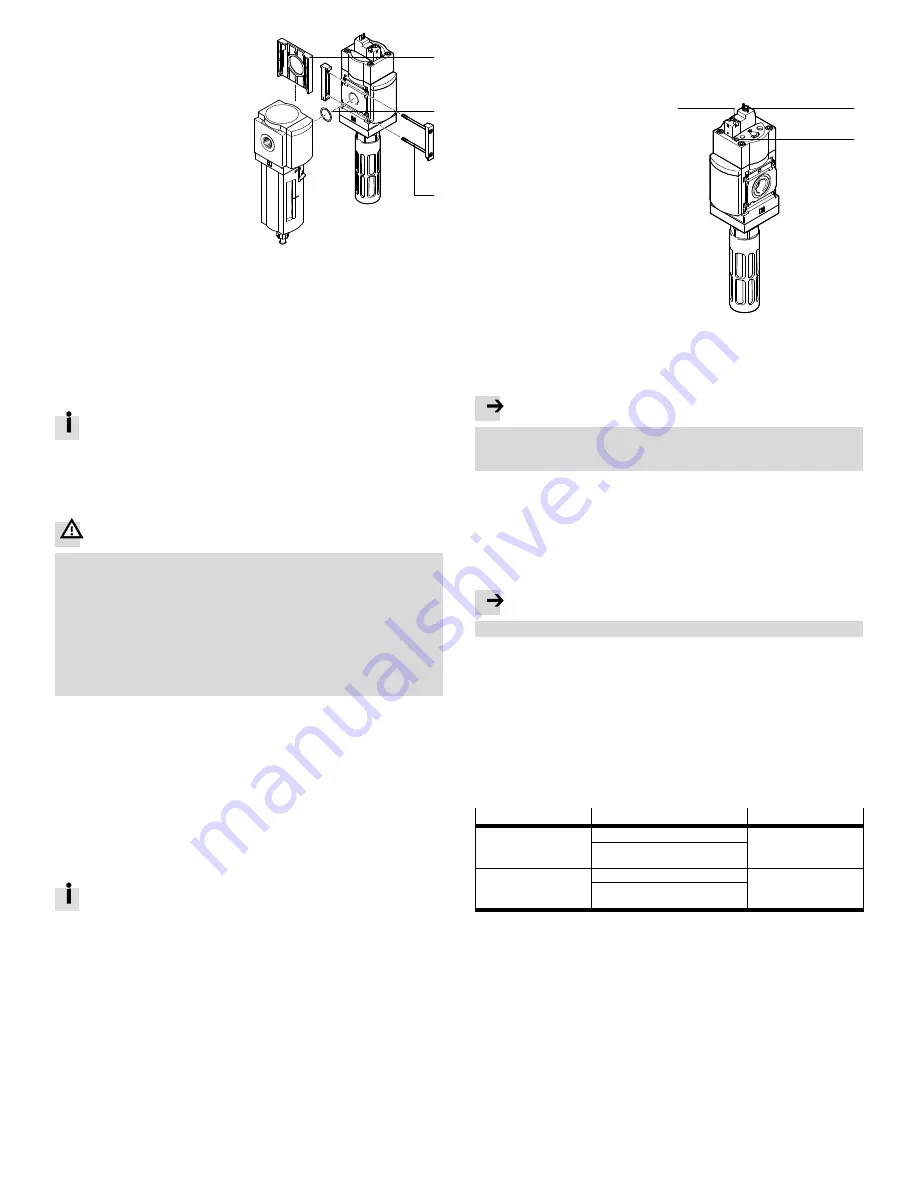

Assembly with MS-series service units

1. Slide any cover cap MS6-END

1

on

the side to be assembled upwards

and remove it.

2. Insert a seal

2

between the indi

vidual devices (module connector

MS6-MV in scope of delivery).

3. Place module connector

3

in

the slots of the individual devices.

4. Fasten the module connector with

two screws (MS6-MV scope of

delivery).

– Max. tightening torque 1.2 Nm.

Fig. 9

Assembly

1

2

3

6

Installation

6.1 Pneumatic installation

Port 1 and 2

If using fittings:

1. Note the permissible screw-in depth of the connecting thread is 10 mm.

2. Make sure that the compressed air lines are connected correctly.

3. Screw the fittings into the pneumatic ports using appropriate sealing material.

Port 3 (thread size G

¾

or NPT

¾

)

Exhausting a system using the MS6(N)-SV-...-C results in high noise levels.

Recommendation: use silencer

è

www.festo.com/catalogue.

1. Screw the silencer into pneumatic port 3.

2. Make sure exhaust is unhindered:

Both the silencer and port 3 must remain unblocked.

6.2 Electrical installation

Warning

Electric voltage – risk of injury due to electric shock.

Electrical connections must only be established when the voltage is discon

nected and by qualified personnel.

MS6(N)-SV-...-C-10V24/10V24P/10V24C/10V24D/V24/V24P

For the electrical power supply, use only PELV circuits in accordance with

IEC 60204-1/EN60204-1 (protective extra-low voltage, PELV).

MS6(N)-SV-...-C-V110/V230

Use only voltage sources in accordance with IEC 60204-1/EN60204-1.

Connect pilot solenoid valve (accessories

è

www.festo.com/catalogue).

7

Commissioning

7.1 Pressurising the product and piping system

1. Apply operating pressure p1 at MS6(N)-SV-...-C.

2. Switch on the supply voltage.

The outlet pressure p2 is built up slowly. The filling time “t” is set through

the main flow control valve attached to the cover (

è

Fig. 6,

7

).

The outlet pressure rises in accordance with the throttle point

è

Fig. 13.

If the preset pressure switching point (PSP) is reached, the main seat of

the valve opens

è

Fig. 14.

The downstream piping system is pressurised.

If the cover (tamper protection) is not mounted, the pressurisation pro

cess is started with the pressure build-up function through operation of

one of the manual overrides (

è

Fig. 6).

Reset manual override

è

7.3 Resetting the internal manual override..

7.2 Cover (tamper protection)

Use:

– In a safety-related system, the setting and control elements must be equipped

with a cover (tamper protection)

è

2.5 Further information.

If the cover (tamper protection) is mounted, the manual overrides cannot be

actuated.

– In a non-safety-related system, use of the cover (tamper protection) is optional.

7.3 Resetting the internal manual override.

A reset will be required if the internal manual override at the soft-start/quick ex

haust valve

8

was previously actuated without the cover (tamper protection)

being mounted.

Resetting can be performed through one of the following measures:

Issue of an electrical signal to pilot

solenoid valve

2

.

or

Actuation of the manual override at

pilot solenoid valve

1

.

Fig. 10 Resetting the internal

manual override

1

2

8

Activation of the internal manual override for feature -10V24C/-10V24D

Activate manual override

8

, if necessary, by removing the threaded pin.

Note

If the internal manual override is activated, it can only be reset through an elec

tric signal to the pilot control solenoid valve

2

, as the pilot control solenoid

valve has no manual override.

8

Operation

If the voltage drops, for example because the power supply is switched off,

the product exhausts the downstream piping system

è

Fig. 5.

After actuation of the internal manual override:

è

7.3 Resetting the internal manual override.

9

Dismounting

Note

Residual pressure must be eliminated before dismantling.

1. Switch off energy sources:

– operating voltage

– compressed air

2. Disconnect the relevant connections of the MS6(N)-SV-...-C.

10

Disposal

When the product reaches its maximum operating time or mission time, it must be

recycled in an environmentally friendly manner in accordance with applicable spe

cifications.

11

Fault clearance

Malfunction

Possible cause

Remedy

Valve switches abruptly.

Pressure switching point is too low.

Correct settings.

Main flow control valve is opened too

far.

Valve does not switch.

Pressure switching point is too high.

Correct settings.

Main flow control valve is not opened

far enough.

Fig. 11 Fault clearance

Repairs to the product are not permissible.

In the event of malfunctions or failure, replace the product and let Festo know

about the failure.

Return defective product to Festo.

12

Maintenance

The product is maintenance-free.

Cleaning

1. Switch off energy sources:

– operating voltage

– compressed air

2. If necessary, clean the product on the outside.

Soap suds (max. +50 °C), petroleum ether and all non-abrasive cleaning agents

may be used.