8

Operation

WARNING

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

Torque on the Piston Rod

During commissioning and operation, the piston rod may only be operated

without torque.

If external torques occur, an external guide must be used.

Lubrication Run During Operation

Observe the following lubrication travel intervals.

• With working stroke less than 2 x spindle pitch... P:

• Perform a lubrication run within 10 travel cycles with a minimum stroke of

≥2.5 x spindle pitch.

9

Maintenance

9.1

Safety

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.

9.2

Checking the cylinder elements

Checking the reversing backlash (ESBF-LS only)

•

Check the reversing backlash of the piston rod at every maintenance interval

(e.g. lubrication interval).

If the maximum permissible reversing backlash is exceeded, the cylinder

should be replaced.

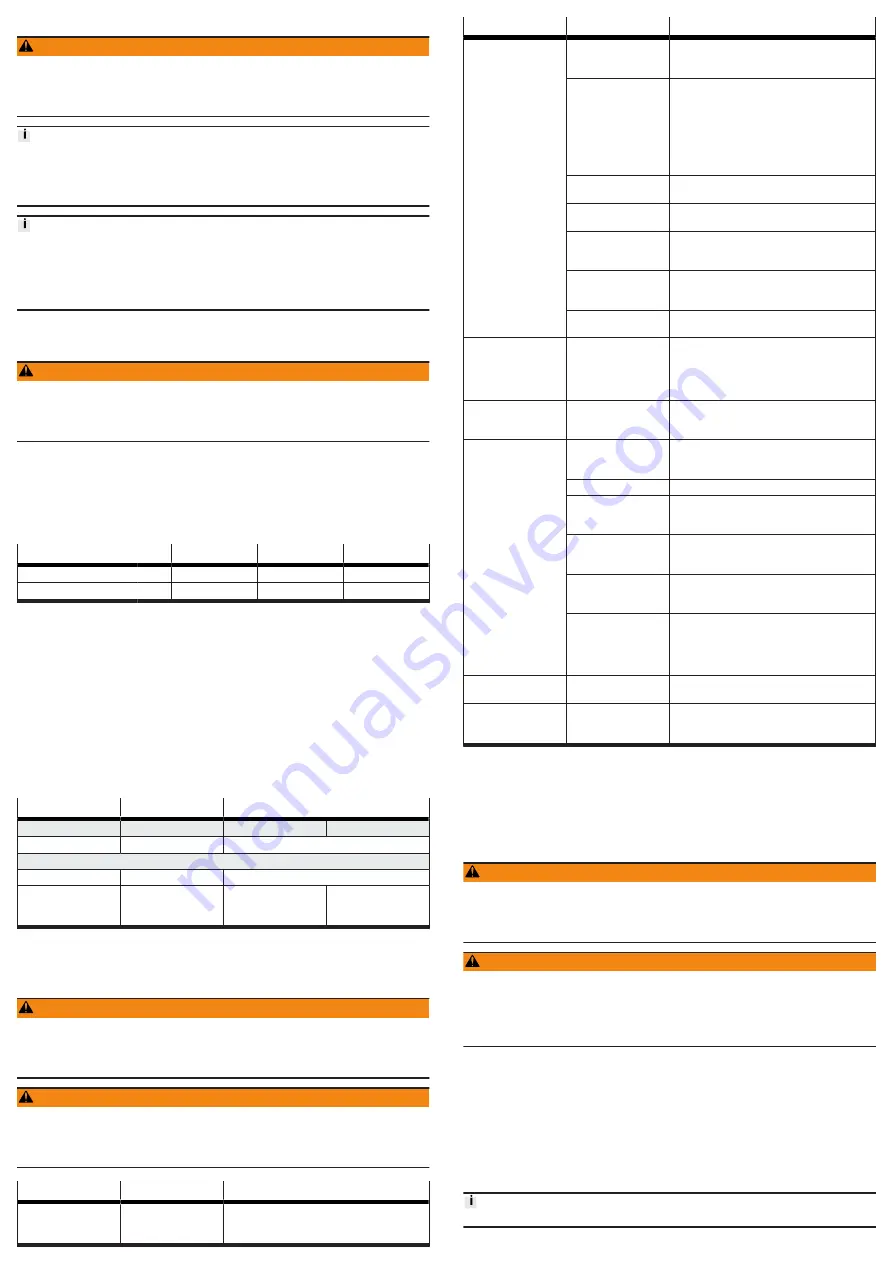

Size

32

40

50

Spindle pitch ...P

2.5

3

4

Max. reversing backlash

[mm]

0.62

0.75

1

Tab. 12: Maximum permissible reversing backlash, ESBF-LS-32/40/50

9.3

Cleaning

–

If the piston rod is dirty, clean it with a clean, soft and lint-free cloth without

cleaning agents and then apply the lubricant thinly to the piston rod.

–

Clean the other product components with a clean, soft cloth and non-abrasive

cleaning agents.

For use with reduced particle emission:

–

Remove abraded particles and dirt from the product:

–

Prior to initial commissioning.

–

Regularly during operation.

9.4

Lubrication

Lubrication Interval and Accessories

Lubrication

Lead screw

Piston rod

ESBF-...

ESBF-...

ESBF-...-F1

Lubrication interval

Lubrication for life

If required, e.g. if the grease layer is too low.

Accessories

Lubrication point

—

Surface

Lubricant

—

Roller bearing grease

LUB-KC1

Roller bearing grease,

suitable for use in the

food industry LUB-E1

Tab. 13: Overview of Lubrication Intervals and Accessories

10

Malfunctions

10.1

Fault Clearance

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.

WARNING

Risk of injury due to unexpected movement of components.

• Protect the positioning range from unwanted intervention.

• Keep foreign objects out of the positioning range.

• Perform commissioning with low dynamic response.

Malfunction

Possible cause

Remedy

Wear on the lead screw

ESBF-LS.

Reversing backlash is

too large.

–

Contact local Festo Service.

–

Replace cylinder

Malfunction

Possible cause

Remedy

Loud running noises

or vibrations or rough

running of the cylinder.

Coupling distance too

short.

Observe permissible coupling spacings

è

Instruction manual for motor mounting kit,

Tensions

–

Install the cylinder so it is free of tension. Note

the flatness of the contact surface

–

Change the layout of the attachment compo-

nent (e.g. payload).

–

Align cylinder and attached guide element par-

allel to each other.

–

Use external guide.

Current controller set-

tings.

Optimise controller data (e.g. velocity, accelera-

tion, ...).

Resonant oscillation of

the cylinder.

Change the travel velocity.

Wear on bearing or

guide.

–

Contact local Festo Service.

–

Replace cylinder

Reversing backlash is

too large.

–

Contact local Festo Service.

–

Replace cylinder

Insufficient lubrication

of the piston rod.

Lubricate the piston rod

Lubrication Intervals and Accessories.

Oscillations at the

piston rod.

Operation at the reso-

nance point of the cyl-

inder.

–

Change the travel velocity.

–

Change the acceleration.

–

Increase the cylinder rigidity (for example

shorter support distances).

–

Change the payload geometry.

Long oscillations of the

profile.

Resonant frequency of

profile and payload too

low.

–

Increase the cylinder rigidity (for example

shorter support distances).

–

Change the payload geometry.

Piston rod does not

move.

Coupling slips.

Check the mounting of the shaft-hub connection

è

Instruction manual for the motor mounting

Loads too high.

Reduce forces and torques. Consider dynamics.

Threaded drive

blocked.

–

Contact local Festo Service.

–

Replace cylinder

Pre-tension of toothed

belt too high in parallel

kit.

Reduce the pretension of the toothed

belt

è

Instruction manual for parallel kit,

Operation at the lower

ambient temperature

limit.

–

Optimise controller data (e.g. velocity, acceler-

ation, ...).

–

Use gear unit.

Piston rod stuck in the

mechanical end posi-

tion.

Manually Releasing a Jam:

–

Switch off the controller and safeguard it from

being switched on again unintentionally.

–

Remove motor and motor mounting kit.

–

Rotate drive shaft freely.

Overruns the end posi-

tion.

Sensor does not

switch.

Check sensor, installation and parameterisation.

Idling torque too high.

Wear in the drive train.

–

Contact local Festo Service.

–

Replace cylinder

Tab. 14: Overview of Fault Clearance

10.2

Repair

–

Observe the instructions for dismantling

–

Send the electric cylinder to the Festo repair service.

–

Information about spare parts and accessories

11

Disassembly

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.

WARNING

Risk of Injury due to Unexpected Movement of Components

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

• Bring moving parts of the product into a safe end position or secure them

against falling.

1. Disconnect electrical installations.

2. Remove the mounted attachment component.

3. Remove the attached accessories.

4. Remove motor and mounting kit.

5. Remove the mounting attachments.

6. Observe transport information

12

Technical data

12.1

Technical data, mechanical

Use the Festo sizing software for sizing the drive