9

Operation

WARNING!

Danger of burns from hot housing surfaces.

Metallic housing parts can reach high temperatures during operation.

Contact with metal housing parts can cause burn injuries.

•

Do not touch metallic housing parts.

•

After the power supply is switched off, let the device cool down to room tem-

perature.

9.1

Master Control

–

Lowest priority: DIO operation (after Power ON and initialisation)

–

Medium priority: IO-Link operation (after established IO-Link communication)

–

Highest priority: HMI operation (unlocked pushbuttons)

9.2

Dimension Reference System

The correct positioning of the drive requires a defined dimension reference sys-

tem.

Linear drive system

–

Ref: reference end position (reference point for Lim

In

, Lim

Out

, Pos

Act

and Pos

Start Press

)

–

motor facing (default)

–

motor facing away

–

Lim

In

/Lim

Out

: end positions

–

Mech

In

/Mech

Out

: mechanical stops

–

Pos

Act

: current position

–

Pos

Start Press

: Start Press Position

.%!.

! .-..*%,

"+). #&')$).$((. #&).

"+).

.

.

.%!. .

! .-..&

#&). #&')$).$((. "+).

"+).

Tab. 2 Dimension Reference System for Linear Drive Systems

9.3

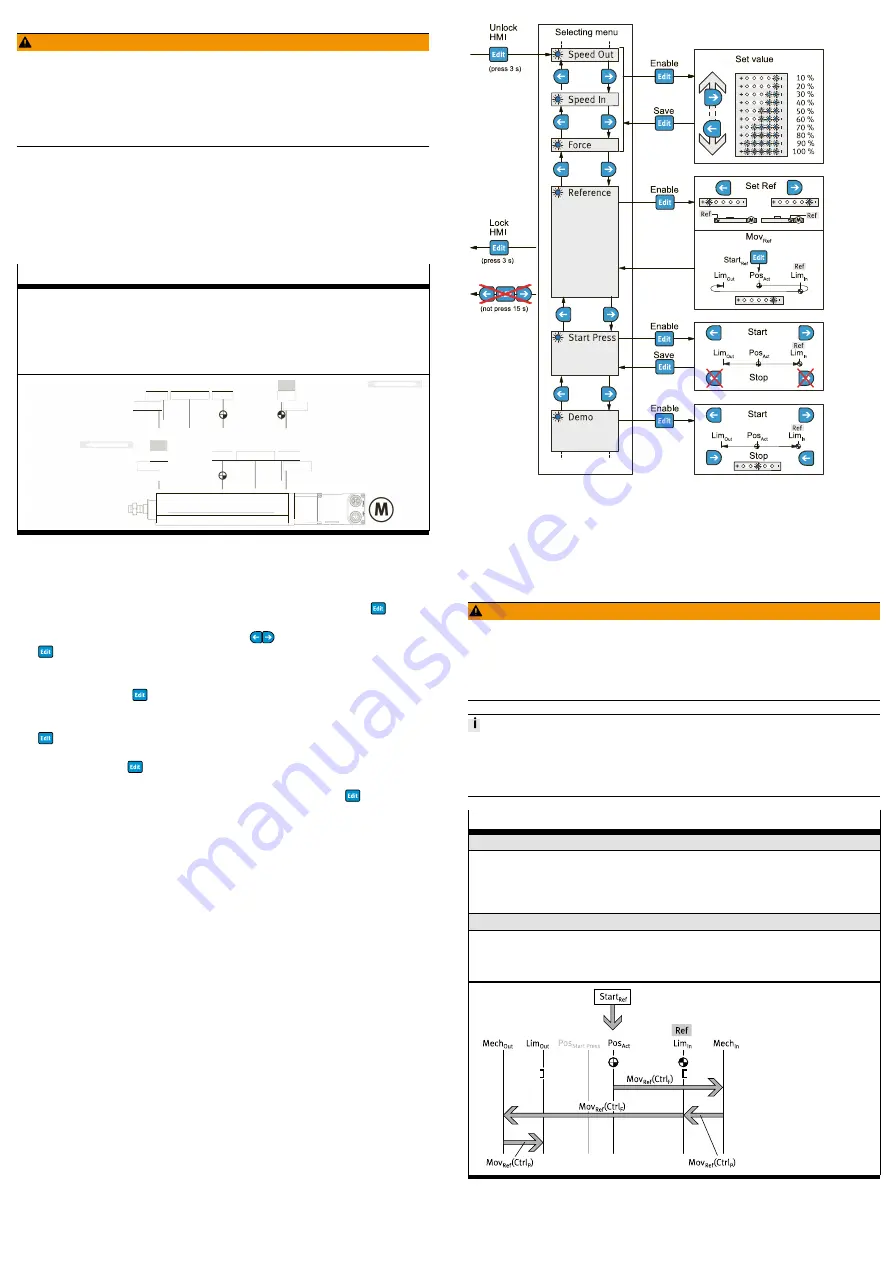

Display and Operating Components (HMI)

The display and operating components (HMI) can be used to perform the follow-

ing functions in the HMI menu:

–

Unlock pushbutton actuators (Unlock HMI), press and hold for 3 s

(Condition for IO-Link operation: IO-Link parameter 0x000C.4 = false)

–

Menu function with pushbutton actuators

select (selecting menu), press

–

Parameterise setpoint values Speed Out, Speed In and Force

(Set value: 10, 20, ..., 100% of maximum value

è

save (Save), press

–

Parameterise the position of the reference end position "Ref" (Set Ref) and

run the homing movement Mov

Ref

(Start

Ref

: Pos

Act

è

Lim

In

è

Lim

Out

), press

–

Run Start Press movement (Start/Stop) and save Start Press Position Pos

Start

Press

(Save), press

–

Execute Demo Run (Start/Stop)

–

Lock pushbutton actuators (Lock HMI), press and hold for 3 s

or no push-

button actuator input for 15 s

Fig. 7 HMI menu

9.4

Homing

During homing, the positions of the mechanical stops Mech

In

/ Mech

Out

are

determined in order to calculate the end positions Lim

In

(Ref)/Lim

Out

for the

dimension reference system.

Before the homing run is carried out, the drive is de-energised for a required re-

initialisation. Then the power supply is restored and the homing process starts.

WARNING!

Risk of injury due to unexpected movement of components.

When starting the homing run, the drive is disconnected from the power supply

for a short time. This can cause unexpected movements of the connected mechan-

ics and crush parts of the body.

•

Bring moving parts of the connected mechanical system into a safe position.

•

A new homing is only necessary if the reference end position Ref or the useful

range is changed.

•

When homing, the Start Press Position Pos

Start Press

is equated with the new

end position Lim

Out

.

Homing

Parameterise reference end position "Ref"

HMI:

–

Menu, Reference

è

9.3 Display and Operating Components (HMI)

IO-Link (acyclic device data):

–

motor facing (default): 0x0103.0, reference = false

–

motor facing away: 0x0103.0, reference = true

Control homing

HMI:

–

Start

Ref

: menu, reference

è

9.3 Display and Operating Components

IO-Link (acyclic device data):

–

Start

Ref

:

0x0104.0, Execute Mov

Ref

= true

Tab. 3 Parameterise and Control Homing

9.5

End-to-end Operation

In end-to-end operation with or without press function, the unit can be moved

between the end positions Lim

In

/Lim

Out

.