Note

Unsuitable mounting techniques can reduce the service life of the ELGR/ELGG

considerably.

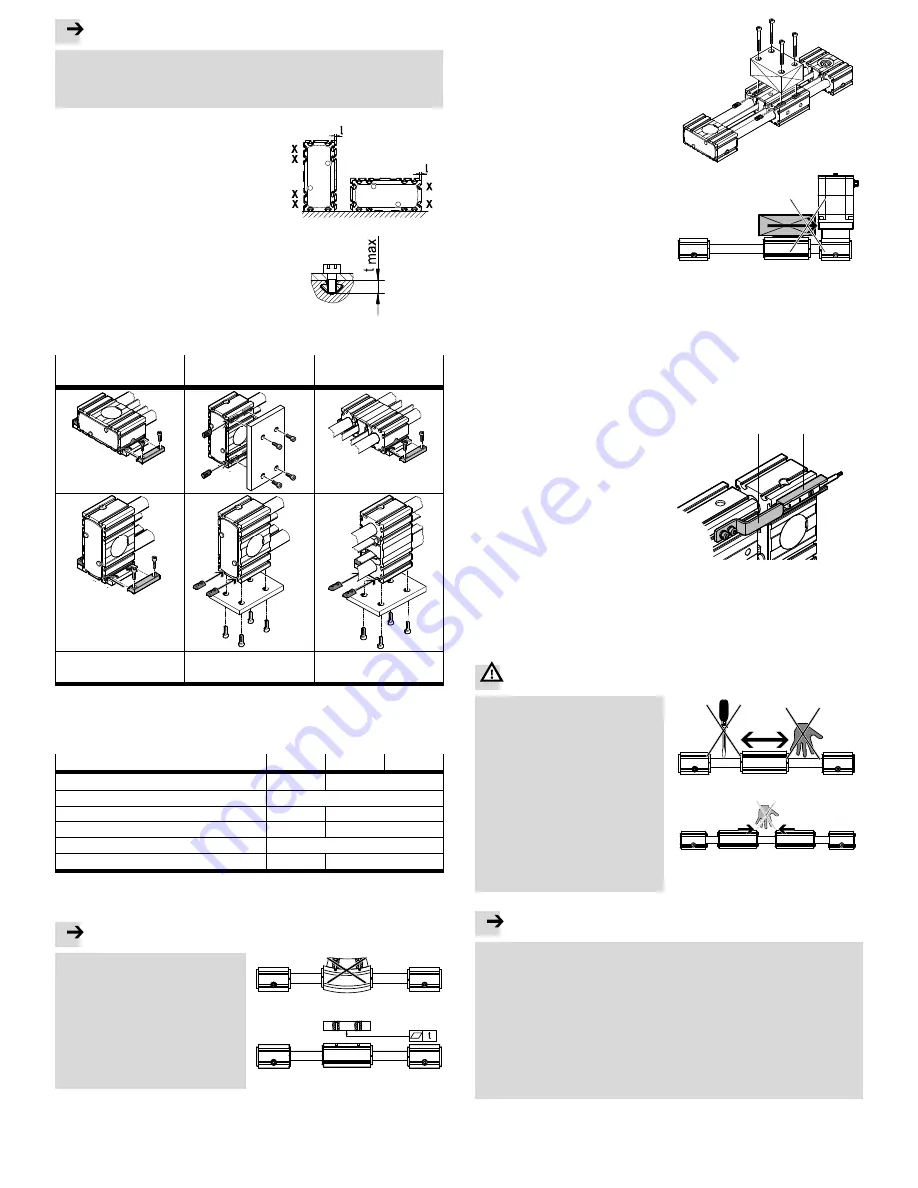

Make sure that the mounting components are outside the positioning range of

the slide (e.g. projecting slot nuts).

Take into account the asymmetric

geometry of the ELGR/ELGG.

Depending on the orientation, the

slide unit or bearing cap projects

beyond the contour by the dimension

l (observe position X of the proximity

sensor).

Fig. 4

Observe the screw-in depth t

max

when using slot nuts (

è

Fig. 7).

Attach the ELGR/ELGG and, if avail

able, the central support (

è

Fig. 6).

Fig. 5

Please select the corresponding accessories from our catalogue

(

è

www.festo.com/catalogue)

Profile mounting

with MUE

Slot nut mounting with

NST

Central support with

MUE/NST (ELGG only)

Profile mounting in the

groove

7

Slot nut mounting in the

slot

7

Profile or slot nut

mounting in the slot

7

1)

1)

Attach the central support centrally, otherwise the stroke will reduce

Fig. 6

Tighten the mounting screws evenly.

The tightening torque is summarised in the following table.

ELGR/ELGG-...

35

45

55

Screw

M3

M5

Centring sleeve

ZBH-7

Slot nut

NST-3-M3

NST-5-M5

Screw-in depth t

max

(

è

Fig. 5)

[mm]

3.8

6

Projection l (

è

Fig. 4)

[mm]

2

Tightening torque

[Nm]

1

5

Fig. 7

5.2 Installation of the payload

Note

If the aluminium slide is bent against a

curved payload, the service life of the

guide will be reduced.

Make sure that the mounting

surface of the payload is even to

within t ≤ 0.01 mm.

Fig. 8

Place the payload so that the pull-

out torque from the force (parallel to

the axis of motion) and lever arm re

mains low.

Fasten the payload to the slide with

4 screws and slot nuts as well as

centring elements, if needed.

(Tightening torque

è

Fig. 7).

Fig. 9

For load geometries with projection in

the longitudinal direction of the slide:

Make sure that the payload does not

strike against the motor or bearing

cap and, in the case of the ELGG,

against the central support.

Fig. 10

5.3 Electrical installation

To protect the end positions against uncontrolled overtravel:

Check whether additional hardware proximity sensors are necessary.

If inductive proximity sensors are used as hardware limit switches:

Use proximity sensors with normally-closed function.

The normally closed function protects the ELGR/ELGG against overrunning the

end position if the proximity sensor cable is broken.

Use proximity sensors that correspond to the input of the controller being used.

If proximity sensors are used as reference switches:

Attach the kit with switch lug (S) and

sensor bracket (L) according to the

assembly instructions (

è

Catalogue

specifications,

www.festo.com/catalogue).

Avoid external influences from

magnetic or ferritic parts in the

vicinity of the proximity sensors

(minimum distance of 3 mm).

Fig. 11

(S)

(L)

To avoid contamination:

Select the appropriate slot covers from our catalogue (

è

Catalogue specifica

tions, www.festo.com/catalogue).

6

Commissioning

Warning

Payloads can cause personal injury

and material damage (risk of

crushing).

Make sure that, in the positioning

range:

– nobody can place his/her hand in

the path of the moving components

(e.g. through a protective guard),

– there are no foreign objects in the

path of the moving components.

It should not be possible to touch

the ELGR/ELGG until the load has

come to a complete standstill.

Fig. 12

Note

Incorrect specification values of the braking ramp in STOP situations (e.g.

EMERGENCY STOP, Quick Stop) result in an overloading of the linear axis and can

destroy it or drastically reduce its service life.

Check the settings for all braking ramps in the controller or the higher-order

control system (deceleration values and jerk).

Taking the travel speed, moveable load and mounting position into account,

make sure that the delay values (brake delay and delay times) are set in such

a way that the maximum drive torque or feed force of the linear axis used is

not exceeded.

Use the “Positioning Drives” sizing software from Festo to design the linear

axis (

è

www.festo.com).