DDPC

Festo – DDPC –

201905b

English

7

In the case of direct fastening or use of mounting accessories in each case with cylinder collar hole

milling:

Select a mounting option (e.g. from the following table).

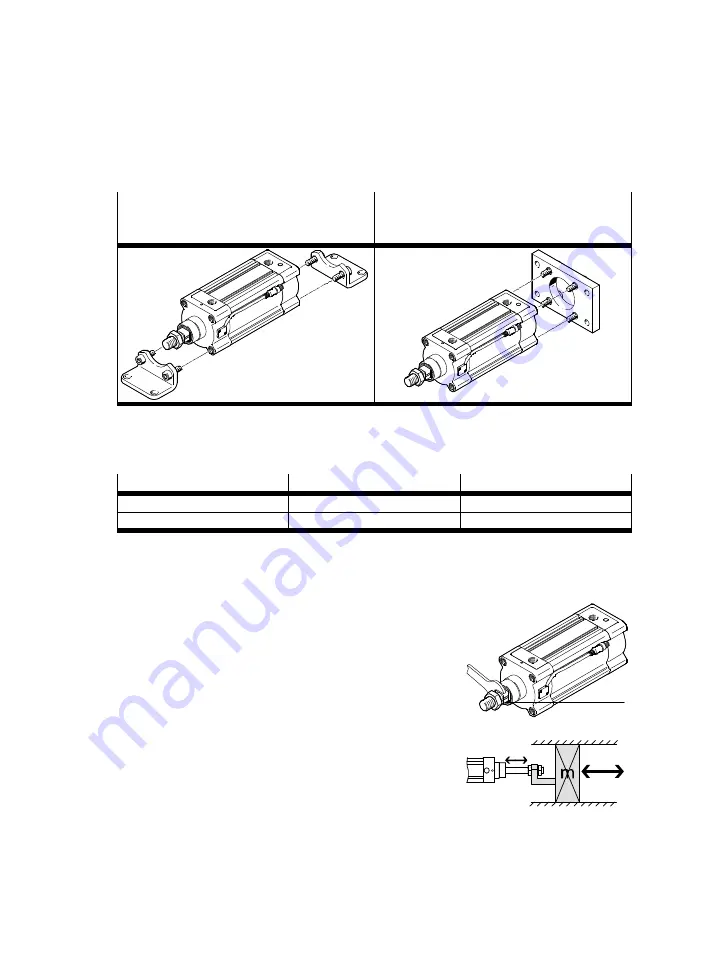

Double screw connection with HNC foot

mounting in the threaded holes of the cover

screws

Quadruple screw connection with FNC flange

mounting in the threaded holes of the cover

screws

Tab. 2

Tighten the mounting screws evenly.

The different product sizes have the following connecting threads and tightening torques:

Size

80

100

Connecting thread

M10

M10

Tightening torque

[Nm]

10 + 2

10 + 2

Tab. 3

If accessories are mounted on the piston rod:

Use the following elements:

–

only the thread of the piston rod.

–

the square piston rod

5

for counter pressure

(only in the retracted end position).

The maximum torque on the bearing must not exceed 5 Nm.

Fig. 2

5

–

an external guide for the work load.

This will prevent lateral loads on the piston rod.

Lateral loads produce false measurement results and may

damage the measuring system.

Fig. 3