6.2

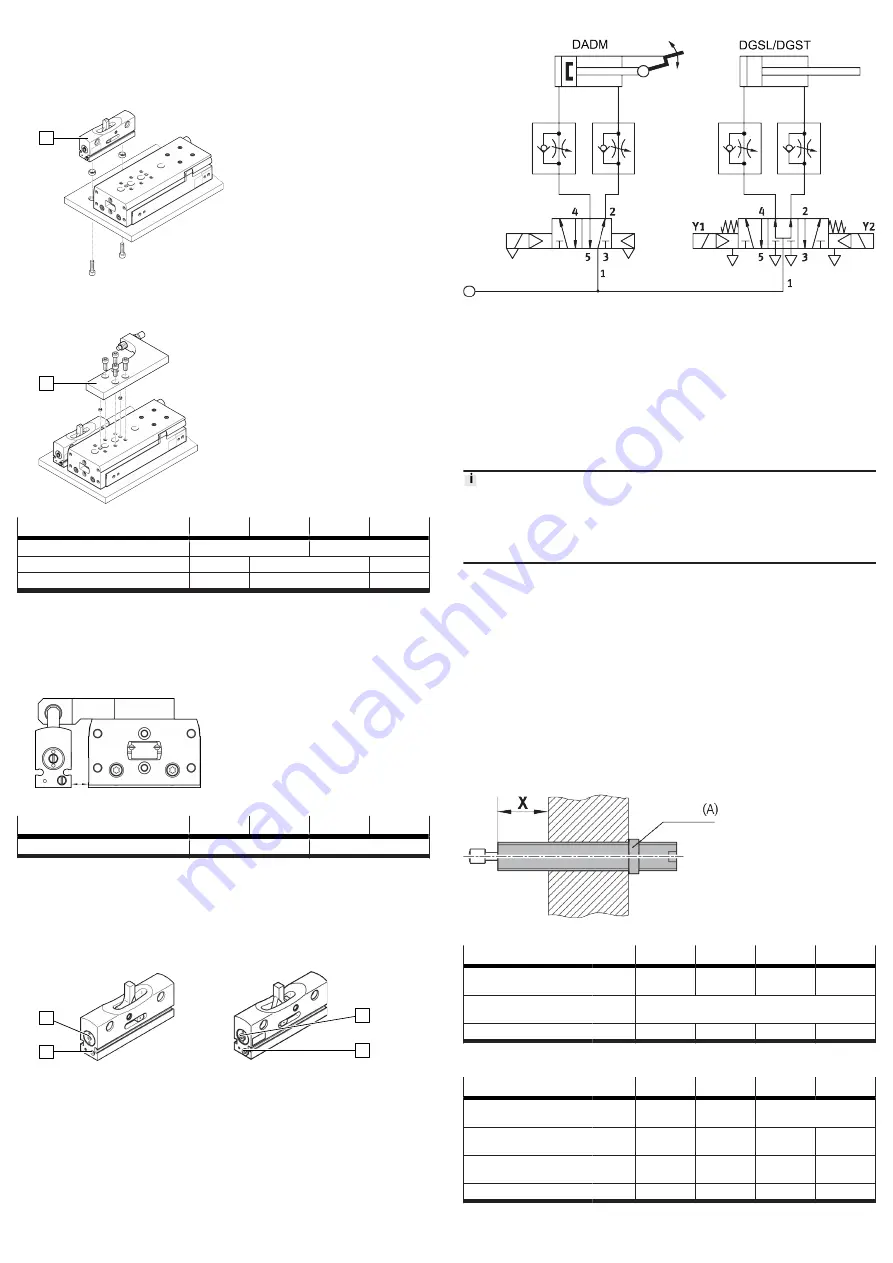

Mounting intermediate position module on linear drive DGST

1. Fasten the intermediate-position module to the mounting surface underneath

with two screws and the accompanying centring sleeves . Tightening torque

Tab. 1 Tightening torque for mounting the intermediate position module.

The intermediate position is fine-tuned during commissioning by screwing the

cushioning component in or out.

7

2. Fasten the shock absorber retainer to the slide of the linear drive with four

screws . Tightening torque

Tab. 3 Tightening torque for mounting shock

absorber retainer on linear drive DGST.

6

DGST

-12

-16

-20

-25

Centring sleeve

Æ

5H7

Æ

12H7

Screw

M4

M5

M6

Tightening torque

[Nm]

2.9

5.2

8.4

Tab. 3: Tightening torque for mounting shock absorber retainer on linear drive

DGST

6.3

Required signal-to-noise ratio

Signal-to-noise ratio

When mounting the intermediate position module on the linear drive DGST, the

required signal-to-noise ratio must be observed

Fig. 2: Signal-to-noise ratio

DGST

-12

-16

-20

-25

Signal-to-noise ratio

[mm]

³

10

³

15

Tab. 4: Signal-to-noise ratio

7

Pneumatic installation

1. Connect pneumatic port 1 and pneumatic port 2 with tubing. Tightening

torque:

–

DADM-EP-G6-10: 0.5 Nm

–

DADM-EP-G6-16: 2 Nm

9

8

9

8

2. Seal unused ports with blanking plugs.

Possible control of a DADM in connection with DGSL/DGST

Fig. 3: Control of DADM with DGSL/DGST

8

Electrical installation

For sensing the stop lever positions:

1. Use suitable proximity switches with a longitudinal cable outlet

2. Place the proximity switches in the slots of the intermediate-position module.

3. Mount the proximity switches in the corresponding end position. A minimum

distance of 10 mm from magnetic parts must be observed.

9

Commissioning

Malfunctions may occur if excessive loads are applied to the stop lever.

• The following must be considered in this context:

• The stop lever must be retracted and advanced at the correct time.

• Briefly switch off pressure to the linear drive to retract the stop lever or

pressurise both sides.

1. Push the slide of the linear drive manually to the end position from which it is

to approach the intermediate position.

2. Pressurise the linear drive so the approached end position is retained.

3. Pressurise pneumatic port 1 on the intermediate-position module.

–

If required: the stop lever can be pressurised via the sliding pad . The

sliding pad serves as a manual override.

Ä

The stop lever extends.

4. Start a test run with low switching frequency and low impact speed. Linear

drive operating instructions

5. Slowly accelerate the payload on the linear drive. The slide of the linear drive

must not make a hard stop against the intermediate-position module.

6. If necessary: adjust the intermediate position by screwing in or unscrewing

the cushioning component on the shock absorber retainer . Maintain the

screw-on length X and the tightening torque A of the lock nut .

7. Terminate the test run.

Fig. 4: Screw-in length X and tightening torque A DADP-ES-G6/DADP-ES-G8

DADP-ES-G6

-10

-16

-20

-25

Screw-on length X with

DGSL-…-PA/-P1A/-Y3A

1)

[mm]

0 … 25.5

0 … 39.5

0 … 49.5

0 … 49

Screw-on length X with

DGSL-…-EA

1)

[mm]

0 … 5.5

Tightening torque A

[Nm]

3

5

8

20

1) Maximum adjustable end-position range

Tab. 5: Screw-on length X and tightening torque

DADP-ES-G8

-12

-16

-20

-25

Screw-on length X with

DGST-…-Y12A

1)

[mm]

0 … 13.6

0 … 15.7

0 … 20

Screw-on length X with

DGST-…-PA/P1A

1)

[mm]

0 … 19

0 … 21.5

0 … 25

0 … 35

Screw-on length X with

DGST-…-EA

1)

[mm]

0 … 7.6

0 … 9.85

0 … 5.5

0 … 2

Tightening torque

[Nm]

2

3

5

8

1) Maximum adjustable end-position range

Tab. 6: Screw-on length X and tightening torque