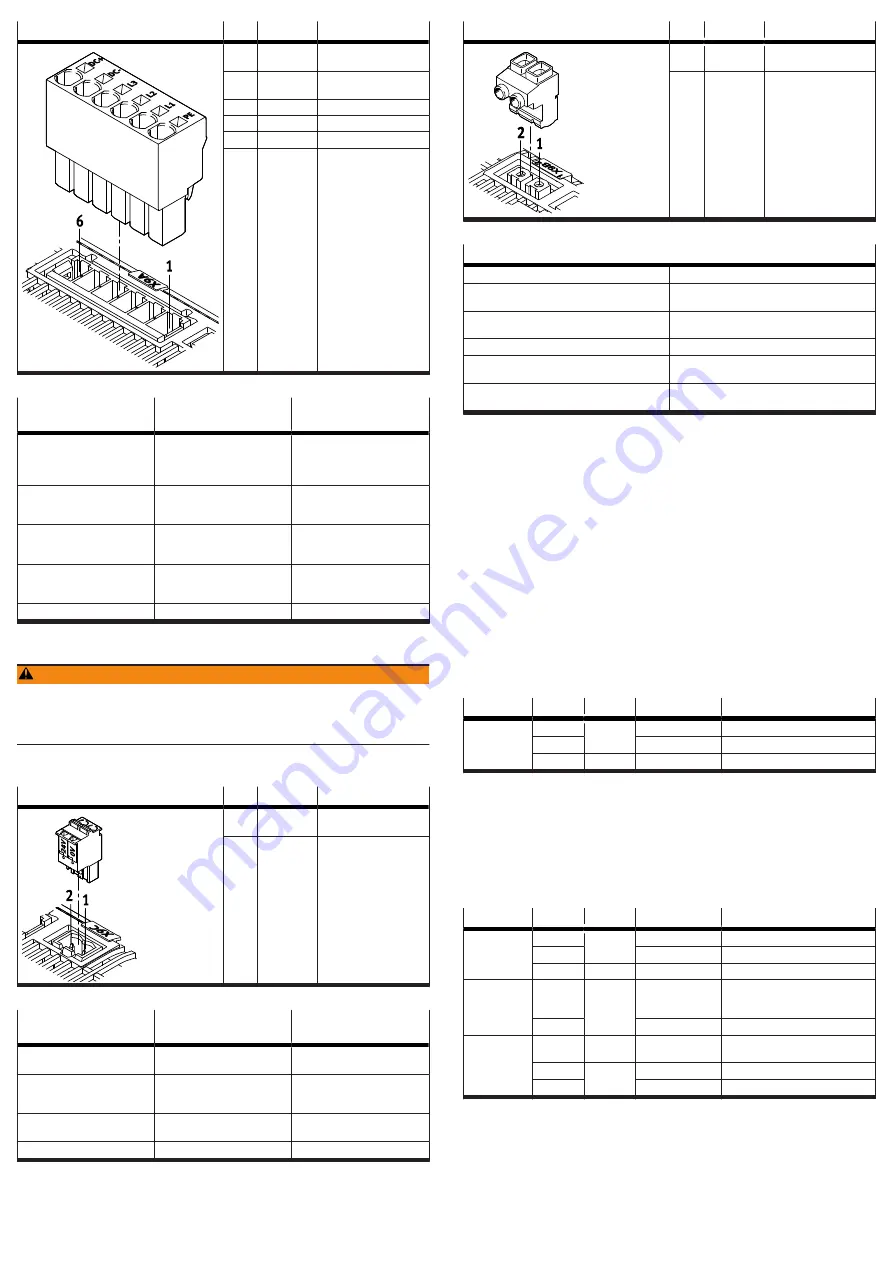

[X9A]

Pin

Function

Description

6

DC+

DC link circuit positive

potential

5

DC-

DC link circuit negative

potential

4

L3

Mains supply phase L3

3

L2

Mains supply phase L2

2

L1

Mains supply phase L1

1

PE

Protective earthing

Tab. 37: Power supply and DC link circuit

Requirements for the

connecting cable

Single device

Device compound

Number of insulated wires and

shielding

4 insulated wires, unshielded

without DC link coupling:

4 wires, unshielded

with DC link coupling: 6 wires,

unshielded

Min. conductor cross section

including wire end sleeve with

plastic sleeve

0.5 mm

2

1.5 mm

2

Max. conductor cross section

including wire end sleeve with

plastic sleeve

4 mm

2

4 mm

2

Max. conductor cross section

including wire end sleeve

without plastic sleeve

6 mm

2

6 mm

2

Max. length

2 m

£

0.5 m

Tab. 38: Requirements for the connecting cable

7.10.2

[X9C], logic voltage supply

WARNING

Risk of injury due to electric shock.

• For the electrical power supply with extra-low voltages, use only PELV circuits

that guarantee a reinforced isolation from the mains network.

• Observe IEC 60204-1/EN 60204-1.

•

Only connect PELV circuits with an output current of max. 25 A. Otherwise,

use a separate external fuse: 25 A.

[X9C]

Pin

Function

Description

2

24 V DC

positive potential of logic

voltage supply

1

0 V

Reference potential for

logic voltage supply

Tab. 39: Logic voltage supply

Requirements for the

connecting cable

Single device

Device compound

Number of insulated wires and

shielding

2 insulated wires, unshielded

2 insulated wires, unshielded

Min. conductor cross section

incl. wire end sleeve with

plastic sleeve

0.5 mm

2

0.5 mm

2

Max. conductor cross section

incl. plastic wire end sleeve

2.5 mm

2

2.5 mm

2

Max. length

2 m

0.5 m

Tab. 40: Requirements for the connecting cable

7.10.3

[X9B], connection for braking resistor

The connection [X9B] is located on the top of the device. The internal braking

resistor or a suitable external braking resistor is attached to the connection [X9B].

[X9B]

Pin

Function

Description

2

BR+Ch

Braking resistor positive

connection

1

BR-Ch

Braking resistor negative

connection

Tab. 41: Connection for the braking resistor

Requirements for the connecting cables of external braking resistors

Number of insulated wires and shielding

2 wires, shielded

Min. conductor cross section incl. wire end

sleeve with plastic sleeve

0.25 mm

2

Max. conductor cross section incl. plastic wire

end sleeve

2.5 mm

2

Max. cable length

2 m

Wiring

inside the control cabinet, shield connected to

PE

Tightening torque of the screw terminals on the

mating plug GIC 2.5 HCV/2-ST-7.62

0.5 … 0.6 Nm

1)

1) Specification of the manufacturer at the time the documentation was approved

Tab. 42: Requirements for the connecting cable

Selection of suitable braking resistors

Information on selecting suitable braking resistors

è

Manual Assembly, Installa-

tion.

7.11

Cross-wiring

Cross-wiring makes it possible to set up a device compound consisting of up to 10

servo drives CMMT-AS. The different cross-wiring options are as follows:

–

Cross-wiring of I/O signals at the connection [X1A]

–

Cross-wiring of the mains and logic voltage supply without DC link coupling

–

Cross-wiring of the mains and logic voltage supply with DC link coupling

Information on cross-wiring

è

Manual Assembly, Installation and Manual Safety

sub-function.

7.12

STO installation

Inputs and outputs for the safety sub-function STO

The 2-channel request for the safety sub-function is made via the digital inputs

#STO-A and #STO-B. The STA diagnostic output indicates whether the safe status

has been reached for the safety sub-function STO.

Connection Pin

Type

Identifier

Function

[X1A]

X1A.11

DIN

#STO-B

Safe torque off, channel B

X1A.12

#STO-A

Safe torque off, channel A

X1A.22

DOUT

STA

Safe torque off acknowledge

Tab. 43: Inputs and outputs for the safety sub-function STO

7.13

SBC installation

Inputs and outputs for the safety sub-function SBC

The 2-channel request for the safety sub-function is made via the digital inputs

#SBC-A and #SBC-B at the connection [X1A]. The SBA diagnostic output indicates

whether the safe status has been reached for the safety sub-function SBC. The

holding brake is connected via the connection [X6B]. The external clamping unit is

connected via the connection [X1C].

Connection Pin

Type

Identifier

Function

[X1A]

X1A.9

DIN

#SBC-B

Safe brake control, channel B

X1A.10

#SBC-A

Safe brake control, channel A

X1A.21

DOUT

SBA

Safe brake control acknowledge

[X1C]

X1C.1

DOUT

BR-EXT

Output for connection of an

external clamping unit (high-side

switch)

X1C.5

GND

Reference potential (ground)

[X6B]

X6B.1

–

FE

Functional earth connected to pro-

tective earth

X6B.2

OUT

BR+

Holding brake (positive potential)

X6B.3

BR–

Holding brake (negative potential)

Tab. 44: Inputs and outputs for the SBC safety sub-function

7.14

SS1 installation

Inputs and outputs for the safety sub-function SS1

The safety sub-function SS1 is wired like the safety sub-function STO but is

supplemented by the functional input CTRL-EN so that the braking ramp can be

activated by the safety relay unit.