25

7.6 Switch for percussion drilling

Fig. 5

• Slide the switch to the “Drill” symbol for

normal drilling.

• Slide the switch to the “Hammer” symbol for

percussion drilling.

7.7 User tips

• Drilling in tiles

To avoid slipping away, stick some tape on

the tile. Drill calm on low speed and adjust

the machine to normal drilling (not impact

drilling).

• Choosing the correct drill

Put the screw into the the chuck. Tighten the

chuck. Now you can find the correct size

drill.

8. SERVICE & MAINTENANCE

Make sure that the plug is removed

from the mains when carrying out

maintenance work on the motor.

8.1 Maintenance

The machines have been designed to operate

over a long period of time with a minimum of

maintenance. Continuous satisfactory opera-

tion depends upon proper machine care and

regular cleaning.

8.2 Cleaning

Regularly clean the machine housing with a

soft cloth, preferably after each use. Keep

the ventilation slots free from dust and dirt.

If the dirt does not come off use a soft cloth

moistened with soapy water. Never use sol-

vents such as petrol, alcohol, ammonia water,

etc. These solvents may damage the plastic

parts.

8.3 Lubrication

The machine requires no additional lubrication.

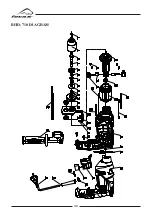

8.4 Faults

Should a fault occur, e.g. after wear of a part,

please contact the service address on the war-

ranty card. In the back of this manual you find

an exploded view showing the parts that can

be ordered.

8.5 Environment

To prevent damage during transport, the app-

liance is delivered in a solid packaging which

consists largely of reusable material. Therefore

please make use of options for recycling the

packaging.

Faulty and/or discarded electrical or

electronic apparatus have to be col-

lected at the appropriate recycling

locations.