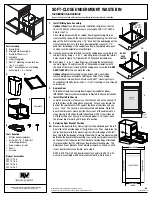

5.

Pull out the equalizing element.

6.

Pull out the filter element with the removal

tool that is supplied with the filter element or

with small pliers.

7.

Install a new filter element and a new

equalizing element.

8.

Install the filter cover and tighten it to 22,5 ±

2,5 Nm with a 27 mm spanner.

GUID-3F4B1B80-BA08-47A5-B5E8-9825DC7FEF33-low.jpg [Low]

Fig. 33

9.

Make sure that the surface around the DEF connector is absolutely clean.

IMPORTANT:

Dirt in the inlet connector can cause a failure of the DENOX2.2-system!

a) Use a vacuum cleaner to remove all particles around the DEF connector.

b) Examine the parts for crystallized DEF particles.

c) If necessary, clean the parts carefully with warm and clean water.

d) Dry the parts carefully.

Do not use compressed air!

10.

Remove the DEF connector.

Do not let dirt in the connection of the supply module!

11.

Install the new DEF connector.

a) Use a new O-ring.

b) Lubricate the O-ring with glycerin based lubricant.

Do not use oil!

c) Turn the DEF connector on its position and tighten it to 4-5Nm.

12.

Put the old equalizing element, filter element and the DEF connector to a correct disposal point.

1.6.10 Maintenance to be made every two years

1.6.10.1 Change coolant

(1)

Drain plug on radiator

(2)

Drain plug on cylinder block

(3)

Drain plug on oil cooler

(4)

Bleed plug

Change the coolant every two years. This ensures

that the anti-corrosive is always active. See

information for coolant quality requirements.

GUID-06D0CE8F-7E47-4747-87DD-F4712A58C83F-low.jpg [Low]

Fig. 34

Procedure

1.

Drain the cooling system.

a) Remove the filler cap.

[V]

GUID-0E452FE8-8E70-401A-8851-CE80DFF8BDB2 [V2]

1. General

Rubber Track Tractor

1-37

79037272A