Operation instructions

Warning

1.

Before starting the machine, look into the feeding chamber to make sure that it is empty.

2.

Keep your face and body away from the feed intake opening.

3.

Do not allow your hands or any other part of your body or your clothing to get inside the

feeding chamber, discharge chute, or near any moving part.

4.

Keep proper balance and footing at all times. Do not overreach. Never stand at a higher

level than the base of the machine when feeding material into it.

5.

Always keep the discharge zone clear when operating this machine;

6.

When feeding material into the machine be extremely careful that pieces of metal, rocks,

bottles, tins or other foreign objects are not included.

7.

If the cutting mechanism strikes any foreign objects, or if the machine should start making

any unusual noise or vibration, shut off the motor and allow the machine to stop. Unplug

the connection cable (to disconnect the electric unit from the power supply) and take the

following steps:

a)

inspect for damage;

b)

check for and tighten any loose parts;

c)

have any damaged parts replaced or repaired with parts having equivalent

specifications.

8.

Do not allow processed material to build up in the discharge zone; this may prevent proper

discharge and can result in kickback of material through the feed intake opening.

9.

If the machine becomes clogged, shut off the motor and unplug the connection cable (to

disconnect the electric unit from the power supply) before clearing any debris. Keep the

motor (ventilation slots) clear of debris and other accumulations to prevent damage to the

motor or possible fire.

10. Keep all guards and deflectors in place and in good working condition.

11. Do not transport this machine while the motor is running.

12. Shut off the motor and unplug the connection cable (to disconnect the electric unit from the

power supply) whenever you leave the work area.

13. Do not tilt the machine while the motor is running.

14. When using the device the collection box must be securely in position and the safety switch

is locked.

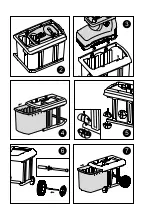

Feeding

Feed the material to be chopped into the right side of the feeding tunnel. The material is

automatically pulled in by the chopping knife.

Caution! Longer material standing out from the machine could lash out when being pulled

in by the chopping knife! Keep a safety distance!

Warning! Always use the pusher (Fig.11) if you try to push the material into the feeding

tunnel. Do not use your hands directly! Keep the pusher well after use.

Only insert as much material as will not block up the feeding tunnel.

Chop garden waste that has been stored for some days and is wilted and damp alternately with

branches.

This will prevent the chopping knife from getting blocked up.

Do not fill into the shredder any soft material such as kitchen waste instead of compositing it.

Widely branched material with leaves must be completely chopped before any new material is

fed in.

Take care that the chopped material can freely fall from the discharge chute – danger of backing

up!

The ventilation slots must not be covered by the waste bag or the chopped material.