15

- Check the cleanliness of boiler lamellas. If these are dirty then after draining water off the appliance

demount the heat exchanger and flush it by water jet. After drying the heat exchanger is to be sprayed

by heat resistant silver paint to prevent flue-gas corrosion.

- In case of boilers older than 4-5 years inside the coil scale or other deposits may develop (this effect

is signed by rumbling of the boiler). Deposits deteriorate efficiency to a high degree. Flush by solution

of acid is needed. It is to be done in a workshop where an acidifying instrument (plastic pump), a

protecting equipment, the possibility of compactness check and of pipe loss measurement is provided

and the laws of environment protection may be kept entirely.

- Every mark referring to a leakage is to be terminated by change of seals.

- Check compactness of gas armature.

- Check gas quantity. In case of deviation adjust it to the specified or desired value.

- Check close of gas valves and safe operation of thermoelectric flame cut-out and flue-gas backflow

sensor.

- Check pull of flue-gas.

- Check safety temperature limiter.

- Check operation of electronic control panel.

- Check thermistor, grease of contact surfaces with heat-conductive metal paste.

- Check operation of room thermostat.

In case of detecting a fault during these checks, terminate it immediately.

The technician is liable to make a note and justify it with his signature on the accomplishment of

periodic maintenance. In this case the withdrawal of warrant letter is PROHIBITED. Maintenance is

not an action of guarantee.

3. Instructions for use and maintenance for users

First installation of the appliance may only be made by an expert of the service network of NOVUM-

FÉG Ltd. He is bound to get convinced of the proper operation and mounting of the appliance and

after a test operation to instruct the user about handling.

Operating of the heating equipment is the following:

Connect the appliance by opening the shut-off valves to the heating system properly filled up

with water. Open the gas valve located before the appliance.

3.1. Ignition

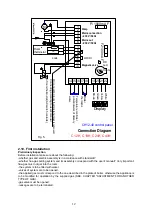

Push the knob located on the front of the appliance until it butts on (see Fig. 8.).

- Light the pilot flame by a match.

- Keep the button pushed for about 15 seconds after lighting the pilot flame. On releasing the

button the flame must keep on burning.

3.2. Operating

Attach mains to the heating equipment. Only earthed socket may be used! After attachment to mains

the pump carries out a 1-minute pre-circulation without heating.

On room thermostat adjust the desired temperature. After this the operation of heating

equipment is entirely automatic, by switching on-off the main burner it keeps the temperature

of the room constant.

3.3. Advice for economical operating

If you spend a longer while outdoors decrease the temperature set on the room thermostat! It is

advisable to reduce the temperature for nights as well. By this way an energy saving of 8-10% can be

reached.

Decrease of delivery water to 70-75 ºC increases the lifetime of boiler and the feeling of comfort. It

may be achieved by the adjustment knob of water temperature controller located at the bottom of

electric box (Temperature controller knob Fig. 8.).