7

MAINTENANCE MANUAL: MODELS 860, LF860, 860U & LF860U

1

/

2

"- 2" (15 – 50mm)

Check Module Re-Assembly

Use reverse procedure for assembly with the following

special instructions .

1 . Inspect the check module O-ring (Item 3 .1) for damage and replace if

necessary . To ease assembly, apply a thin coating of supplied lubricant

to the O-ring (Item 3 .1) prior to installing in body .

CAUTION

!

Excess lubricant may cause foreign debris to collect on internal compo-

nents which could foul the check assembly and result in a test failure .

2 . The word

INLET

is inscribed on the end of each module . That end

should face the inlet of the valve .

3 . When installing the check modules On the Series 860 Reduced

Pressure Assembly, make sure the check assembly with the heavy

duty spring is inserted in the inlet bore of the body (1st check posi-

tion) . Ensure the orientation of the 1st check assembly is positioned

so that one (1) of the four (4) flow path windows faces down towards

the Relief Valve . The check assembly with the weaker spring must be

installed in the outlet bore of the body (2nd check position) .

4 . When replacing spacer (Item 8) between the two check assemblies, be

sure that the flanged end of the spacer is touching the back side of the

inlet check assembly so that the cover will fit properly . Next, replace

cover making sure #3 test cock is on the upstream side . Do not over

tighten cover bolts (Approximately 35 inch

•

pounds is sufficient) .

5 . After reassembling, close test cock #2, #3 and #4 (test cock #1 should

already be closed), slowly open inlet ball valve . Bleed air from the unit

by opening and closing test cock #2, then #3 and finally #4 .

NOTICE

During the bleeding process on the Series 860, the relief valve may

discharge a high volume of water until all test cocks have been closed

and pressure stabilized .

6 . Check for external leaks and repair if necessary . Slowly open

outlet ball valve .

7 . Test assembly in accordance with the locally approved test methods .

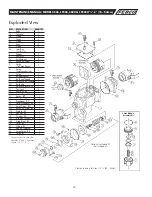

Relief Valve Repair

NOTICE

Discharge from the relief valve assembly may not indicate a relief valve

failure . The relief valve will discharge water when the mainline check

valves become fouled with foreign debris . See Troubleshooting Guide for

more information

BEFORE

disassembling the relief valve .

1 . Slowly close inlet and outlet ball valves . Bleed off air from the unit by

opening and closing test cock #2, then #3, and finally #4 . Test cock #1

should remain closed .

2 . Loosen brass cylinder in center of relief valve cover (Item 18) by

unscrewing

1

/

4

turn (counterclockwise) . Remove the relief valve cover

bolts (Item 21) and relief valve cover (Item 19) .

3 . The internal relief valve assembly module will be attached to the relief

valve cover . Unscrew the brass cylinder and remove from cover . Grasp

the outer diameter of the large outer diaphragm (Item 15) and pull

away from the cover until the small outer diaphragm (Item 16) comes

out through the relief valve cover hole and is completely separated

from the relief valve cover . Discard old internal relief valve assembly

module . Remove the plastic slip rings (Item 18 .1) and discard . Slide out

the seat ring (Item 12) and seat gasket ring (Item 12 .1) from the relief

valve body and discard .

4 . Apply a thin coating of supplied lubricant to both sides of the new seat

gasket ring (Item 12 .1), and slide it on the short end of the new seat

ring (Item 12) . Slide the short end of the new seat ring into the hole of

the relief valve body . (The adhesion from the lubricant will hold the seat

ring in place during the rest of the assembly process .)

NOTICE

If applying new diaphragms from a rubber kit, make sure that the

smooth rubber side of each diaphragm, is facing outward. Before

assembly.