- 19 -

DYNA POWER 350CV

、

503CV

、

500CV

、

630CV

、

630HCV Operating Manual

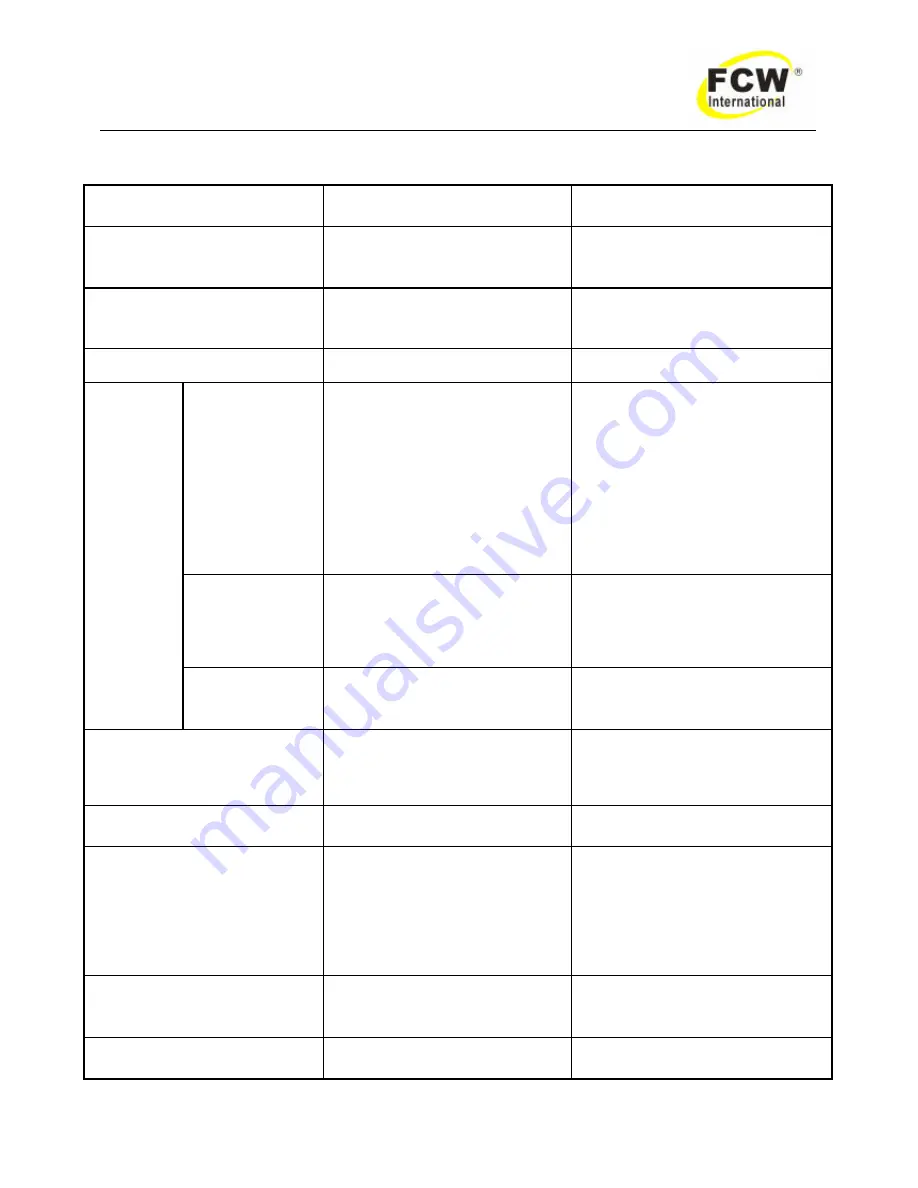

Troubleshooting Guide

Fault

Cause

Remedy

1. The AC power indicator light is

not lit and welding arc can not

be established.

1. No power input or main power

switches damage.

2. Indicator damage.

1. Check input power or replace

main power switch.

2. Replace indicator light.

2. The AC power indicator light on

and welding arc can not be

established.

1. Input voltage unstable.

2. Diode damage.

1. Connect stabilizer or reset power

switch.

2. Replace diode.

3. The warning indicator light on.

Over load.

Reduce current or wait moment.

a. No gas flow

No wire feed

No output

1. MIG torch plug is not insert into

the socket or the connect is

bad.

2. MIG torch damage (diagnose

method: make the welding

machine control socket two

pins short circuit, the faulty

disappear).

3. Wire feeder plug is not insert

into the socket or the connect

condition is bad.

1. Insert the plug correctly, and

rotate it clockwise.

2. Repair or replace MIG torch.

3. Insert the plug correctly, and

rotate it clockwise.

b. No gas flow

Have wire feed

Have output

1. The gas line is not turn on.

2. The MIG torch damage.

3. The solenoid damage.

4. Wire speed Control board

damage.

1. Turn on the gas system.

2. Repair or replace.

3. Repair or replace.

4. Repair or replace.

4. Turn on

torch

control

switch

c. Have gas flow

Have wire feed

No output

1. Disconnect the work piece to

the work ground cable.

2. Main Board damage.

1. Reconnect the ground cable and

tighten the work piece.

2. Repair or replace.

5. Faulty welding arc control.

1. The MIG torch damage.

2. Faulty setting.

3. Main board damage.

1. Repair or replace the MIG torch.

2. Read this manual carefully and

set up correctly.

3. Repair or replace.

6. The arc weld has no output.

1. Transformer bad connect.

2. AC contactor bad connect.

1. Repair or replace.

2. Repair or replace.

7. Arc start difficult or often break

off.

1. The power supply voltage is too

low or the cable is too thin.

2. Main board damage.

3. The contact tip damage.

4. The work piece bad connect.

5. The wire roller damage.

6. The torch lead damage.

1. Connect a stabilizer or increase

the thickness of the power cable.

2. Repair or replace.

3. Repair or replace.

4. Repair or replace.

5. Replace

6. Replace

8. The maximum output welding

current can not achieved in the

rated input voltage.

Main board damage.

Repair or replace.

9. The current decrease in the

weld process.

Faulty cable connected to work

piece.

Make sure the cable positive connect

to the work piece correctly.