CAP-835

24

4.2 Brief description

The fresh air supplied by the installed cooling air

fan is filtered through the intake filter. The air

flows through the intake valve into the

compressor airend, where it is compressed

together with the injected oil to the final

pressure. The oil is largely separated from the

compressed air in the oil separator tank. The

air/oil separator removes the remaining oil from

the compressed air. The compressed air then

flows through the minimum pressure and non-

return valve into the air after-cooler and is

cooled down before it leaves the screw

compressor via the discharge port.

The oil is separated from the compressed air in

the oil separator tank and the air/oil separator

and flows to the oil cooler. The oil temperature

thermostat adds the cooled oil to the hot oil via

the oil cooler bypass according to the set point

temperature. Finally, the oil filter cleans the oil

before it is injected into the compressor airend

again.

4.3 Assembly description

4.3.1

Enclosure doors

Only qualified personnel may remove the

enclosure doors with the included special

wrench. Enclosure doors are a part of the

electric shock protection and reduce the sound

level emitted by the unit.

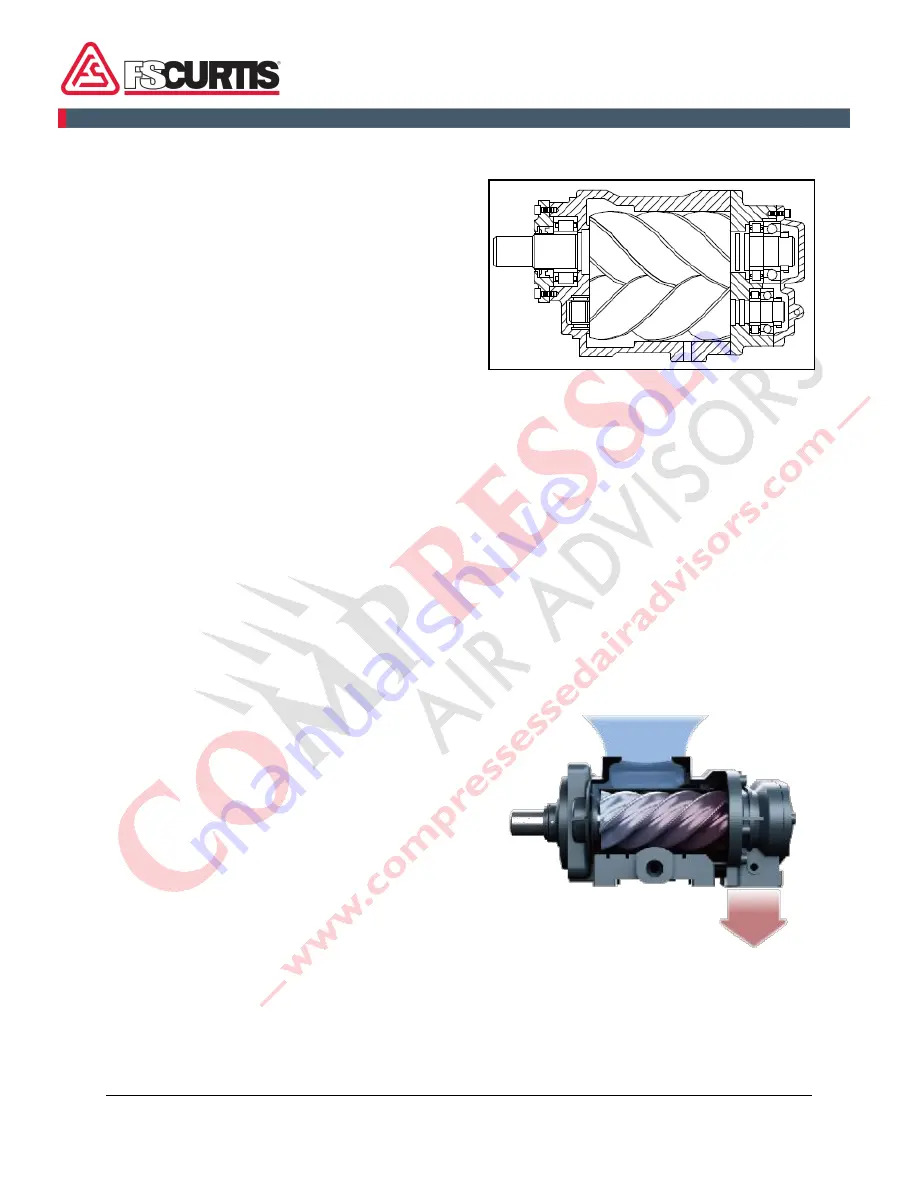

4.3.2

Screw Compressor

The compressor assembly is an oil flooded

positive displacement, single stage, helical

screw type unit consisting of two rotors or

screws supported axially by roller bearings and

enclosed in a housing or stator as depicted in

the sectional view.

4.3.2.1

Drive unit

Belt and direct drive units are installed in the

screw compressors. They differ in construction,

their technical data and their functional principle

as follows:

In operation as depicted above in the compression

cycle, air entering the compressor through the inlet

port becomes trapped between the helical lobes of

the main rotor and the matching grooves of the

secondary rotor. As the rotors turn air is trapped in the

cavity created by the meshing lobe and groove and

reduced in volume or “compressed”. It is then pushed

through the successive cavities until it reaches the

discharge end of the compressor and is sent to the oil

separator.

During the compressor cycle, oil is injected into the

compressor for the purpose of dissipating the heat of

compression and to seal the internal clearances. The

compressed air laden with oil leaves the compressor

through the discharge port and enters a reservoir

where the oil and air are separated. This process

delivers a smooth flow of compressed air at the

desired pressure.