OPERATING INSTRUCTIONS

Roseville, MN

Ph. 1-800-444-2373

Fax. 651-645-7390

www.fastestinc.com

WP120 Rev C, 3/14/2014

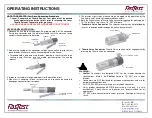

TEST PIECE

MEDIA PORT

SQUEEZED HANDLE

POSITION

REMOVAL

INSERTION

PILOT PORT

THUMB VALVE

PILOT PORT

HANDLE

SQUEEZED

MEDIA PORT

SLEEVE

BODY

NOTE TO OPERATOR: Test Piece Connection Procedure.

1. Lever, Pneumatic or Thumb Control. Test piece must be pushed

firmly against piston inside collets prior to releasing the Lever,

Thumb Valve or Pneumatic pilot pressure.

2. ALWAYS MAKE SURE SLEEVE IS THREADED TIGHT TO BODY.

LEVER HANDLE OPERATION:

1. Squeeze the handle to extend/open the gripping collets of the connector.

Push/place connector onto the male test threads until the main seal o-ring

contacts the component to be tested.

2. Release the handle of the connector, collapsing the collets to grip the test

piece threads. Make sure collets have collapsed inside sleeve.

•

Threaded collets grip onto male threads, drawing in the test piece to the

sealing o-ring. Pressure into the media port completes the sealing

process.

3. Introduce test media through media port for the duration of test.

4. When test is complete relieve test pressure and squeeze the handle to

disengage connector from test piece.

5. The previous four steps of connecting also apply to the operation of the

Pneumatic and Thumb Valve operated connectors.

6. Both the Pneumatic and Thumb Valve connector require pilot port supply of

75-120 psi. Both styles have 1/8” NPT pilot ports.

7.

Pneumatic Valve Connector:

This requires external control provided by

the user to engage and disengage the collets pneumatically.

8.

Thumb Valve Connector:

Thumb Valve controls collet engagement by

pressing the Thumb Valve on connector.

WARNING:

FasTest

Connectors are designed ONLY for the threads meeting the

specifications listed in the

FasTest

literature. DO NOT use in other

threads.

Connectors are NOT designed for permanent connections and are for

temporary connections only.

DO NOT EXCEED pressure rating as marked on connector.

Verify proper connection BEFORE pressurizing. Use only in a safe

environment. Safety chains and guards are recommended for all

applications.

DO NOT move connector while under pressure. Damage or injury may

result.