7

Part #FAST4-101

Revised 7/9/07

FAST™

3400 Democrat Rd.

Memphis, TN 38118

Phone: (901) 260-3278 Fax: (901) 375-3408

www.fuelairspark.com

will run. Check that the cam sensor is properly installed and plugged in. Also check for any wiring

damage between the cam sensor and the XIM™.

STATUS

– In normal operation, this LED lights up when the XIM™ has established CAN

communications with the XFI™ ECU. If it is not lit, check that the CAN LINK on the XIM™ harness

is connected (either directly or through an Interconnect Cable) to the CAN LINK on the XFI™

harness. Also verify that a Terminating Plug and Terminating Receptacle are connected to the open

ends of the CAN wiring.

A flashing status LED indicates that the XIM™ is in flash mode. This is used to update the software in

the XIM™. If flash mode was entered accidentally, make sure the FLASH wire is not touching ground

and power cycle the XIM™.

Setting up the C-Com XFI™ Software

Setting up the software in your FAST™ XFI™ to use the XIM™ is very simple. Select “IPU Ignition”

as the ignition type. Enter the “Crank Ref. Angle (*BTDC)” setting shown in the DIP switch table.

And finally, if using the Crank Trigger or OE Crank Trigger ignition strategies with the Cam input not

occurring before cylinder #1, change the “Cam Sync Precedes Cylinder:” setting. That setting remains

“1” for any of the Factory Specific ignition strategies. That’s all there is to do. Complete step by step

instructions are available under the Help menu in the C-Com XFI™ software under Section 6.0 Initial

Setup.

Flashing your XIM™

If it becomes necessary to update the software within the XIM™, the unit will need to be put into flash

mode. This is done by grounding the FLASH wire while turning on the XIM™. A flashing Status LED

will indicate that the XIM™ is in flash mode. An update utility will be provided that will send the new

software to the XIM™ through the communications cable that links the XIM™ (through the

CALPORT connector) to the laptop. Once the update has been sent, remove the FLASH wire from

ground and power cycle the XIM™ to complete the flashing process.

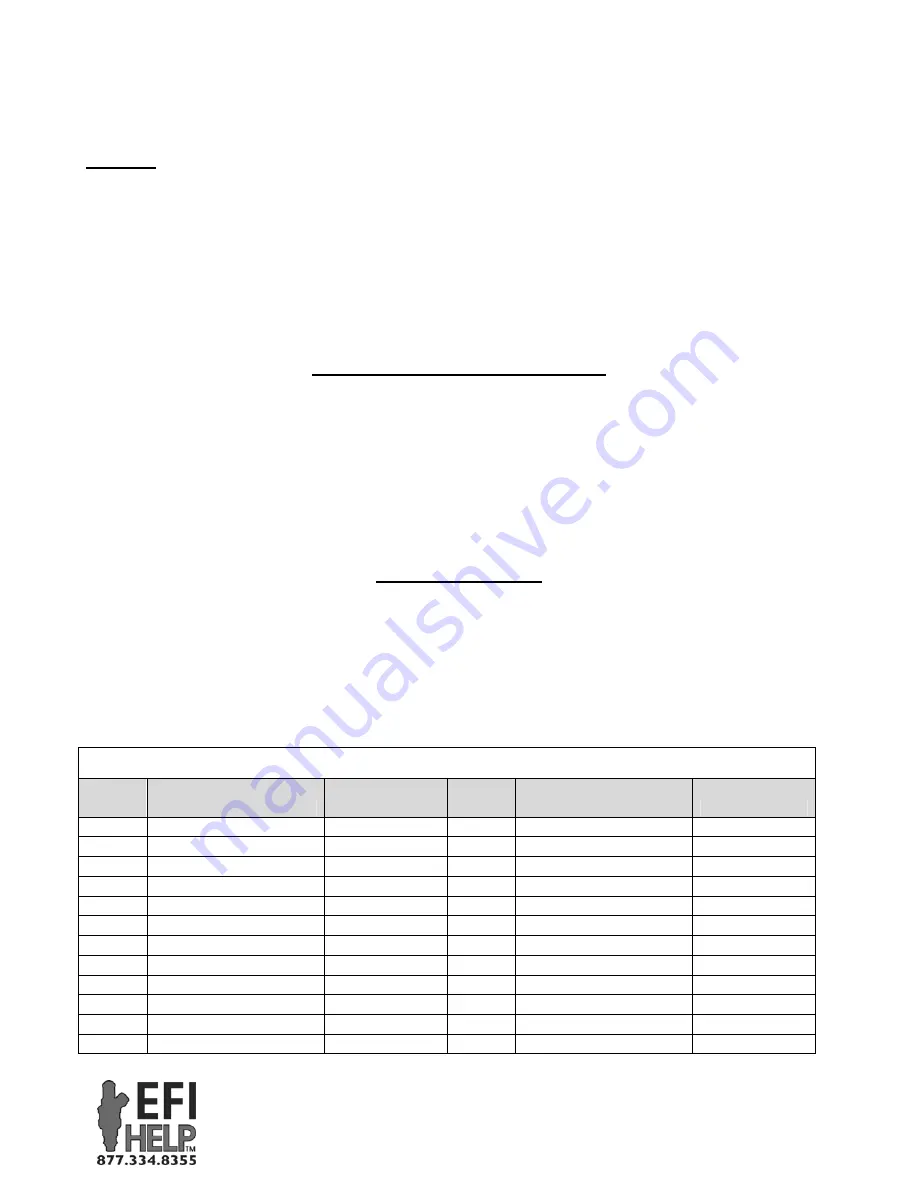

XIM™ Pinout Chart

XIM™

Pin

Function

Wire Color

XIM™

Pin

Function

Wire Color

30-A1

Inductive Crank Input

Red

18-A1

+12V Switched Input

Pink

30-A2

Discrete Crank Input

Yellow

18-A2

User #1*

30-A3

Crank Output

Brown/White

18-A3

Digital GND

Black/White

30-B1

Digital GND

Black (/White)

18-B1

Battery Input

Red

30-B2

Digital GND

Black/White

18-B2

User #0*

30-B3

Cam Output

Yellow/Black

18-B3

N/A*

30-C1

Inductive Cam Input

Red

18-C1

Coil Output A

Orange

30-C2

Discrete Cam Input

Brown

18-C2

Auxiliary Output*

30-C3

Flash Enable Input

Blue

18-C3

Power GND

Black

30-D1

Digital GND

Black (/White)

18-D1

Coil Output D

Purple

30-D2

Digital GND

Black/White

18-D2

Coil Output C

Gray

30-D3

Load Input*

18-D3

Coil Output B

Blue