CHICK-INN

24

Revision date: 12.19.07

CARE AND MAINTENANCE

Proper care and maintenance of the shelter will help to

ensure years of service. The following items identify areas

that should be periodically checked to ensure that your

shelter is maintained properly:

• Regularly check the end panels and main cover to see

that they remain tight and in proper repair.

• Check connections and all fasteners to verify that they

remain tight.

• Do not climb or stand on the shelter at anytime.

• Remove debris and objects that can accumulate on the

shelter. Use tools that will not damage the cover when

removing debris.

• Remove snow to prevent excess accumulation. Use

tools that will not damage the cover when removing

snow.

• Check the contents of the shelter to verify that nothing

is touching the cover that could cause damage.

• Check the anchoring system to ensure that all

components are tight and in good repair.

• If the shelter is moved, inspect all parts and

connections before reassembling.

• For replacement or missing parts, call 1-800-245-9881

for assistance.

NOTE:

With the exception of Truss Arch buildings,

FarmTek® shelters and greenhouses

do not

have any

tested loading criteria.

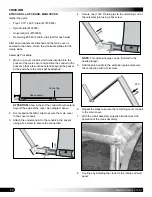

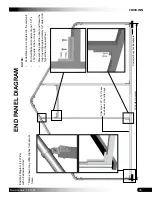

INSTALL ANTI-BILLOW ROPES (CONTINUED)

3. Using the crank assembly, roll the side of the main

cover to its upper-most position and secure it in place.

4. Drill a 1/4" hole

through the main cover

above the

rolled up portion and through the rafter leg pipe in the

locations determined by the rope pattern.

Dashed line shows the location of the end rafter pipe.

ATTENTION:

All eyebolts installed at the tops of the

rafter legs are installed through the main cover and

above the rolled-up portion of the cover.

5. Take one fender washer, place it on one eyebolt, insert

the assembly through the main cover, install another

fender washer, and insert the bolt assembly through

the hole in the rafter leg.

ATTENTION:

All upper eyebolts will include a fender

washer on

each side of the main cover

.

6. Twist a 1/4" locknut onto the eyebolt and tighten the

nut.

7. Repeat Steps 5 and 6 for all remaining upper bolts.

8. Move to the bottom holes, insert an eyebolt, and secure

each with a locknut.

9. Repeat the above procedure until all eyebolts are

installed on both sides of the shelter.

10. With the sides rolled up, thread the rope through the

eyebolts in the desired pattern, cut to length, tie one

end to an eyebolt, pull the rope to remove slack, and tie

the rope to the eyebolt to secure.

11. Roll the side panels to their lowest position.

12. Read the shelter care and maintenance information.

Drill hole above rolled up

portion of the cover.

Содержание Chick-Inn

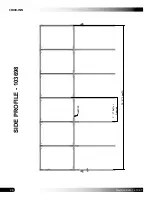

Страница 27: ...27 CHICK INN Revision date 12 19 07 SIDE PROFILE 103697 166P034 Rafter Spacing 3 0 12 0 Length ...

Страница 28: ...CHICK INN 28 Revision date 12 19 07 SIDE PROFILE 103698 166P034 Rafter Spacing 3 0 18 0 Length ...

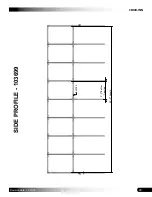

Страница 29: ...29 CHICK INN Revision date 12 19 07 SIDE PROFILE 103699 166P034 3 0 Rafter Spacing 24 0 Length ...