Wheel Lug Nut Torque

When receiving your sprayer or replacing a tire, follow

these steps for ensuring proper lug-nut torque:

NOTE

DO NOT use undersized tires. Use the right size tires

for the job and properly match tires to wheels.

NOTE

DO NOT lubricate threads.

NOTE

Failure to check and maintain the proper lug nut

torque could result in elongation of rim and/or broken

lug-bolts. We recommend checking lug nut torque at

regular maintenance intervals to ensure proper wheel

tightness on your Farm King Sprayer.

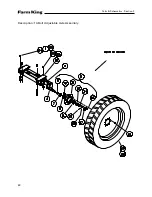

1. Tighten lug nuts to correct torque specifications using

a crisscross pattern.

Size

Torque ft./lb

3/4"-16 UNF

250 - 265

5/8"-18 Bolt

140 - 170

2. After tightening, pull the Farm King 1600 High-

Clearance Sprayer approximately one (1) mile.

3. Retighten lug nuts to correct torque specs.

4. Use the sprayer, stopping after three (3) hours and

again after ten (10) hours to retighten lug nuts to

correct torque specifications.

5. At regular maintenance intervals recheck lug nut

tightness.

Again, we recommend checking lug nut torque at regular

maintenance intervals to ensure proper wheel tightness

on your Farm King Sprayer.

Maintenance, Service & Troubleshooting - Section E

47

Содержание 1600

Страница 1: ...Operator and Parts Manual 1600 High Clearance Sprayer 04 2010 SXL 26030 ...

Страница 5: ...Safety Instruction Section A 5 ...

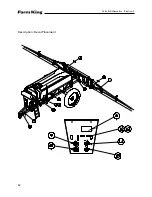

Страница 11: ...Safety Decal Placement Safety Instructions Section A 11 ...

Страница 12: ...Notes Safety Instructions Section A 12 ...

Страница 13: ...Operation Instructions Section B 13 ...

Страница 29: ...Connection Startup Section C 29 ...

Страница 38: ...Connection Startup Section C Notes 38 ...

Страница 39: ...Storage Section D 39 ...

Страница 43: ...Maintenance Service Troubleshooting Section E 43 ...

Страница 50: ...Maintenance Service Troubleshooting Section E Notes 50 ...

Страница 51: ...Parts Schematics Section F 51 ...

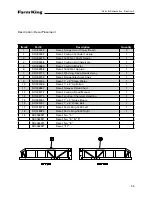

Страница 52: ...19 Description Decal Placement Parts Schematics Section F 52 ...

Страница 54: ...Description Trailer Sprayer Light Kit Assembly Parts Schematics Section F 54 ...

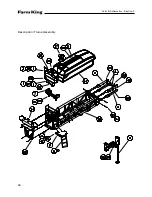

Страница 56: ...Description Frame Assembly Parts Schematics Section F 56 ...

Страница 58: ...Description Drawbar Assembly Parts Schematics Section F 58 ...

Страница 60: ...Description 10 Bolt Adjustable Axle Assembly Parts Schematics Section F 60 ...

Страница 62: ...Description Cradle Assembly Parts Schematics Section F 62 ...

Страница 64: ...Description Tank Spreader and Sight Gauge Parts Schematics Section F 64 ...

Страница 66: ...Parts Schematics Section F Description Fold Over the Top Boom Center Section Assembly 66 ...

Страница 68: ...Description Fold Boom Primary Section Assembly Parts Schematics Section F 68 ...

Страница 70: ...Description Fold Boom Secondary Breakaway Assembly Parts Schematics Section F 70 ...

Страница 72: ...Parts Schematics Section F Notes 72 ...

Страница 74: ...Description Sprayer Hydraulic Routing Parts Schematics Section F 74 ...

Страница 76: ...Description Fold Over The Top Boom Hydraulic Valve Breakdown Parts Schematics Section F 76 ...

Страница 79: ...Parts Schematics Section F Notes 79 ...

Страница 80: ...Description Fold Over The Top Boom 5 Bank Hydraulic Switch Box Breakdown Parts Schematics Section F 80 ...

Страница 82: ...Description Spray Boom Cylinder Assembly Parts Schematics Section F 82 ...

Страница 84: ...Description Boom Rephasing Cylinder Assembly Parts Schematics Section F 84 ...

Страница 86: ...Description Pump Plumbing Parts Schematics Section F 86 ...

Страница 88: ...Parts Schematics Section F Description Tank Plumbing 88 ...

Страница 90: ...Description Raven Control Plumbing Parts Schematics Section F 90 ...

Страница 93: ...Parts Schematics Section F Notes 93 ...

Страница 94: ...Description Valve Mounting 94 Parts Schematics Section F ...

Страница 96: ...Description Fold Over the Top Boom Plumbing Kit Parts Schematics Section F 96 ...

Страница 98: ...Description Manual Fence Row Plumbing Parts Schematics Section F 98 ...

Страница 100: ...Description Eductor Assembly Parts Schematics Section F 100 ...

Страница 103: ...Warranty Section G 103 ...