11

GB

RAC 171

Revisione - 07

Date 10-2010

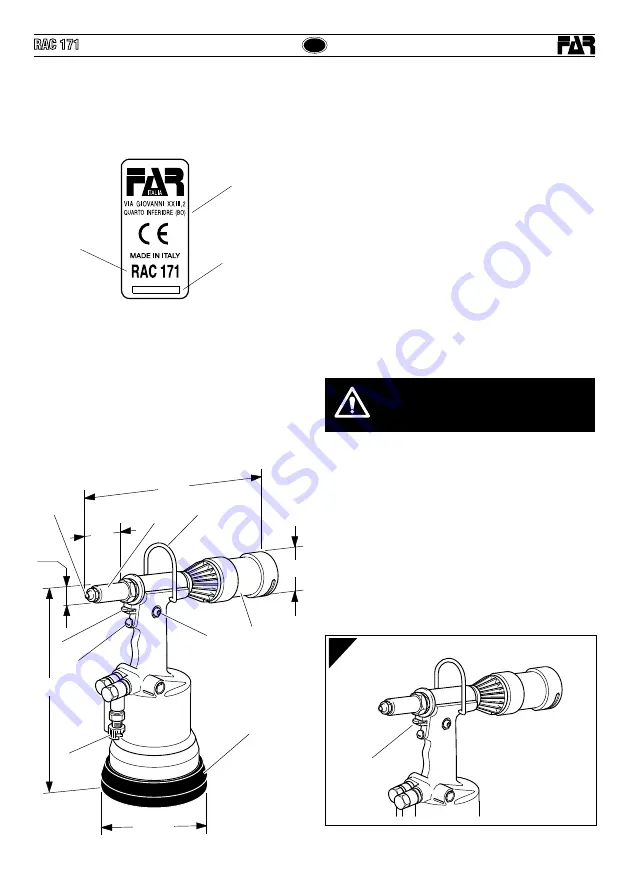

TOOL IDENTIFICATION

The riveting tool

RAC 171

is identified from a marking that

shows company name and address of manufacturer, designation

of the tool, CE mark and year of manufacturing. If any service

is requested, please make reference to the data shown on

the marking.

year of manufacturing

designation of

the tool

MAIN COMPONENTS

A)

................................................................................. Nozzle

B)

............................................................Balancer connection

C)

............................................................................ Nails tank

D)

......................................................... suction opening lever

E)

....................................................... Tensile strenght button

F)

........................................................................Oil tank plug

G)

................................................ Compressed air connection

H)

.............................................................Head carring nozzle

I)

................................................................Protection bottom

340

Ø145

Ø60

Ø24

325

A

H

B

C

G

56

F

I

E

D

TECHNICAL DATA

• Working pressure ......................................................

6 BAR

• Min. int. diam. of the compressed

air feeding hose ...................................

min. diam = 8 mm

• Air consumption per cycle .........................................

10 Lt.

• Maximum force .........................................

6 BAR - 17273 N

• stroke ...................................................................

25.5 mm

• Weight ..................................................................

2,910 Kg

• Working temperature .............................................

-5°/+50°

• Root mean square in total acceleration

frequency (Ac)

to which the arms are subjected ............................

2,2 m/s

2

•

A-weighted emission sound pressure level

.................

67 dBA

•

Peak C-weighted instantaneous sound pressure

......

<130 dBC

•

A-weighted emission sound pressure

.........................

87 dBA

AIR FEED

The air feed must be free from foreign bodies and humidity

in order to protect the tool from premature wear and tear of

the components in movement, therefore we suggest to use a

lubrificator group for compressed air.

HOW TO USE YOUR RIVETING TOOL

(fig.

f1-f2-f3

)

Press lightly for assembling the nails baffle (

L

), as shown in

the figure

f3

.

After the clamping, the sheared nail is piped by the riveting

tool and ejected from the back. By swinging the lever (

D

) you

can activate the suction. By the suction nail system, the rivet

remains in the nozzle also turning over the head of the riveting

tool downwards: this detail increases a lot the usefulness of

the riveting tool.

Do not keep the rivet with your fingers!

If you use the nails tank (

C

), when it is full of nails do not use

the riveting tool. disconnect the tool, unscrew the nails tank (

C

)

and empty it properly.

DO NOT DISPERSE ANY NAIL!

screw

the nails tank (

C

) and start again to work.

WARNING!

Before using the tool, it is compulsory to fit the

nails tank (

C

) and the nails baffle (

L

).

D

f1

Company name

and address