25

abrasive substances or rough cloths will inevitably damage the finish of steel. The steel

surface will be irrevocably damaged if the instructions above are not complied with.

Keep these instructions together with the instructions for use of your hood.

The manufacturer accepts no liability for any damage caused by non-compliance with the

instructions above.

4. CLEANING THE INSIDE OF THE APPLIANCE

The electrical parts or parts of the motor assembly inside the range hood must not be

cleaned using liquids or solvents.

Do not use abrasive products. All the above operations must be performed after having dis-

connected the appliance from the mains power supply.

WARRANTY

M

The new equipment is covered by warranty.

The warranty conditions are provided by the distributor.

The manufacturer is not liable for any inaccuracies in this booklet resulting from printing or

transcription errors. The manufacturer reserves the right to modify its products as it consid-

ers necessary or in the interests of the user, without compromising their essential safety and

operating characteristics.

RANGE HOOD ASSEMBLY

N

(the assembly layout are indicative and valid for the 90 and the 140 with motors version)

Set the hole on the false ceiling, according to the indications of the drawings at the beginning

of the booklet. Fix the provided jig on the internal part of the false ceiling, so not to be visible,

to increase the reinforcement, as indicated in figure (OA-OB-OC).

Note:

if the MU is installed on the hood and on the FC flange connection and the plastic check valve

is used, it is recommended to install the latter on the conveyor outlet. The installation instruc-

tions are found inside the valve packaging.

ATTENTION, the false ceiling must be suitably reinforced to safely support the range hood.

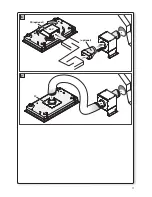

Remove the AP openable panel and the metallic filters (see fig. 1).

Find installation type for outside exhaust version:

With motor unit (UM) (MU) fixed on the range hood:

1) Remove the FC flange assembled on the range hood and the FM flange assembled on the

UM (fig. 1). Define the direction of air outlet by rotating the FL flange of the motor unit (see

fig. 2). Fix UM to the range hood according to the output direction of the wanted air (see fig.

3).

2) Fix the safety chains to the ceiling using the provided screws and wedges (see fig. 4).

3) Lift the range hood near to the false ceiling: connect the UM (MU) motor outlet to the air

discharge duct using a flexible pipe. Carry out electric connection only after having discon-

nected the electric power supply powering the range hood. Introduce the safety chains

inside the made holes in the upper part of the range hood (fig. 5).

4) Place the hood in the false ceiling, which has been previously reinforced. When opened,

hooks G hold temporarily the hood to the false ceiling.

Fasten all screws (B) by rotating them clockwise, so to open the hooks and block the hood

on the panel of the false ceiling.

To remove the hood from the false ceiling, unfasten screws B by rotating them counter-

clockwise, paying attention to hold the hood appropriately to prevent it from falling. Fix the

chain to the hood by using the provided screws and remove the exceeding links. Ensure the

hood is fixed properly to the false ceiling (see fig. 5).

English

Содержание 110030284

Страница 3: ...1 1325 590 96 5 min 10 max 25 1310 620 578 1358 625 150 DIMENSIONE FORATURA HOLE SIZES 1325x590 ...

Страница 6: ...4 505 940 96 5 min 10 max 25 925 493 125 973 540 150 DIMENSIONE FORATURA HOLE SIZES 940x505 505 940 ...

Страница 9: ...7 ...

Страница 10: ...8 AP Magneti Magnets FC 4 5 1 2 3 1A 1B Pulsantiera elettronica interna Electronic pushbutton inside UM FM ...

Страница 11: ...9 A AIR B AIR x8 360 FL UM FL UM 2 3 ...

Страница 12: ...10 ...

Страница 13: ...11 FC FR optional 360 optional 7 6 ...

Страница 14: ...12 Fig 8 ...