Model

kW (net)

Btu/hr (gross)

G1006X O/T

40

150,100

G1006BX S/T

19.5

73,000

G1026X O/T

30

112,500

G1026BX S/T

9.5

35,600

G1060X O/T

45

169,000

G1006FX T/B

21

78,800

G1016/1

10

37,500

G1016/2

20

75,000

G1066X O/T

55

206,500

Configuration

Open Top

Oven

Solid Top

Twin Bullseye

Oven

SIT No. 36 SIT No. 19

Twin Bullseye

G29.2

G24.1

P I L O T B U R N E R S

Natural Gas Propane Gas

é 2.3mm

é 1.4mm

é 2.6mm

Amal 360

é 2.6mm

Amal 360

6x é1.4mm 6x é0.66mm

Solid Top

N26

L11

mbar

inches w.g.

6

14.8

15

37

Natural

Propane

Configuration

Open Top

Oven

Solid Top

Twin Bullseye

kW (net)

Btu/hr (gross)

7.5

28,100

10

37,500

9.5

35,600

5.5

20,600

0mm

X

Figure 1

10.5 - 11mm

7.5mm (+/- 1mm)

1.8 TOTAL RATED HEAT INPUTS -

PROPANE GAS

INDIVIDUAL BURNER HEAT INPUTS -

PROPANE GAS

1.9 INJECTOR SIZES - Natural and Propane Gas

1.10 GAS PRESSURE

A test point is located on the manifold, behind control

panel. Solid top, single and double tier oven model

access is gained by removing the panel as described

in Section 3. Access on open top models is gained by

removing top facia panel.

An adjustable governor is supplied for natural gas

units. Propane unit pressure is controlled by the

incoming supply regulator.

For multiple burner natural gas units, set pressure at

15 mbar with approximately half the total heat input of

the appliance in operation.

1.11 BURNER AERATION

Fixed injectors are fitted and no means of adjusting

the full gas rate is provided. After setting working

pressure as Section 1.10. Check burner aeration.

'X' gap on Natural Gas models - 5mm

'X' gap on Propane Gas models - Fully Open

Oven

An aeration shroud is located close to the injector at

the end of the oven burner. Check that aperture

dimension areas shown in Figure 1. This will achieve

desired cone length. If the burner is over-aerated, the

flame may extinguish at low rates. The correct full

rate cone lengths for natural gas is 25mm. Slightly

yellow flame tips are acceptable on propane units.

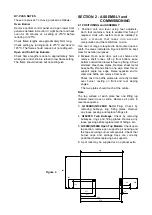

Figure 2

Open Top

Check aperture dimension for natural and propane

gas is as detailed in Figure 2. Check that flame is

stable and there is no evidence of flame lift.

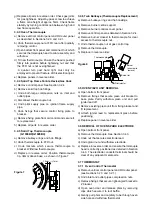

Figure 3A

Figure 3B

Solid Top

Check aeration shroud is located in position shown in

Figure 3A. There should be no flame lift or lightback.

Flames should be blue although slight yellow tipping

is acceptable for propane operation.

Injector should be located centrally within burner

venturi as detailed in Figure 3B.