12

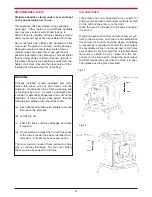

THE ARDMORE WOOD BURNER FUEL NON BOILER STOVE

OPERATING INSTRUCTIONS

When operating and maintaining your Stove respect

basic standards of fire safety. Read these instruc-

tions carefully. All relevant European and National

Standards must be complied with when installing

this appliance. Failure to do so may result in dam-

age to persons and property. Consult your local

Municipal office and your insurance representative

to determine what regulations are in force. Save

these instructions for future reference.

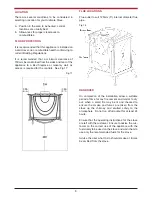

The appliance is suitable for intermittent operation

on wood logs up to a length of 340mm.

All fuels should be stored under cover and kept as

dry as possible prior to use.

Use recommended fuels only, this product is not to

be used as an incinerator or to burn coal or liquid

fuels . The stove must be operated with the doors

closed at all times except for refuelling.

WARNING: This appliance is hot while in opera-

tion and retains its heat for a long period of time

after use. Children, aged or infirm persons

should be supervised at all times and should not

be allowed to touch the hot working surfaces

while in use or until the appliance has thorough-

ly cooled.

IMPORTANT NOTES

1. Do not burn fuel with a high moisture content,

such as unseasoned timber. This will result in a

build up of tar in the stove and in the chimney.

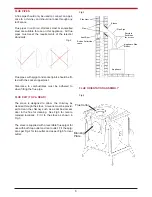

2. Clean the flue-ways of the stove weekly and

ensure that there are no blockages. Check flue-

ways before lighting especially after a prolonged

shut down period. See baffle removal.

3. Never allow a build up of ashes in the ash pan,

as this will cause the grate to burn out prema-

turely.

4. Allow adequate air ventilation to ensure plenty

of air for combustion.

5.

The chimney should be cleaned at least twice a

year by a competent engineer.

6. Regular cleaning of the glass will prevent per-

manent staining. Clean with soapy water when

cool.

7.

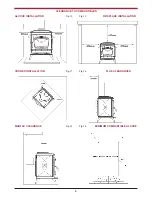

Keep all combustible materials a safe distance

away from unit, please see section for clear-

ances to combustibles.

8. Do not use an aerosol spray on or near the

stove when it is alight.

9.

This appliance is not suitable for use in a shared

flue system.