Greenlee Textron / Subsidiary of Textron Inc.

6

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

Chain Saws with Chain Brake

Inspection

Clean all parts with an appropriate cleaning solution and

dry them thoroughly. Inspect each component as

described in this section. Replace any component that

shows wear or damage.

1.

Ball Bearing (35): Hold the center hub between

your thumb and index finger. Roll the outer surface

against the palm of your other hand. Replace the

bearing if it does not rotate smoothly.

2.

Needle Bearings (24): Insert shaft into bearings.

Spin shaft. If the shaft does not spin smoothly,

replace the entire assembly with bearings already

pressed in.

3.

Saw Head Motor Body (1) and Motor Cap (22):

Inspect mating surfaces, bores, oil passageways,

etc. for grooves or nicks. If any component shows

wear or damage, replace the entire assembly with

bearings already pressed in.

4.

Rim Sprocket (47) and Adapter (45): Inspect all

surfaces, including gear teeth, for grooves or chips.

A minor amount of wear, if it’s consistent among all

of the teeth (an even wear pattern), is acceptable.

The rim sprocket and adapter function as a unit. If

one of them needs to be replaced, replace both of

them. Also, replace the saw chain at the same time.

5.

Guide Bar (55): Clean the oil passage at the base

of the guide bar. Use any instrument small enough

to thoroughly clean the passage.

Check the bar rails for wear by placing a straight

edge against the side of the bar and one cutter.

• Clearance between the bar and the straight edge

indicates that the bar rails are not worn.

• If the chain leans and there is little or no clear-

ance between the bar and the straight edge, the

bar rails are worn and the bar should be replaced.

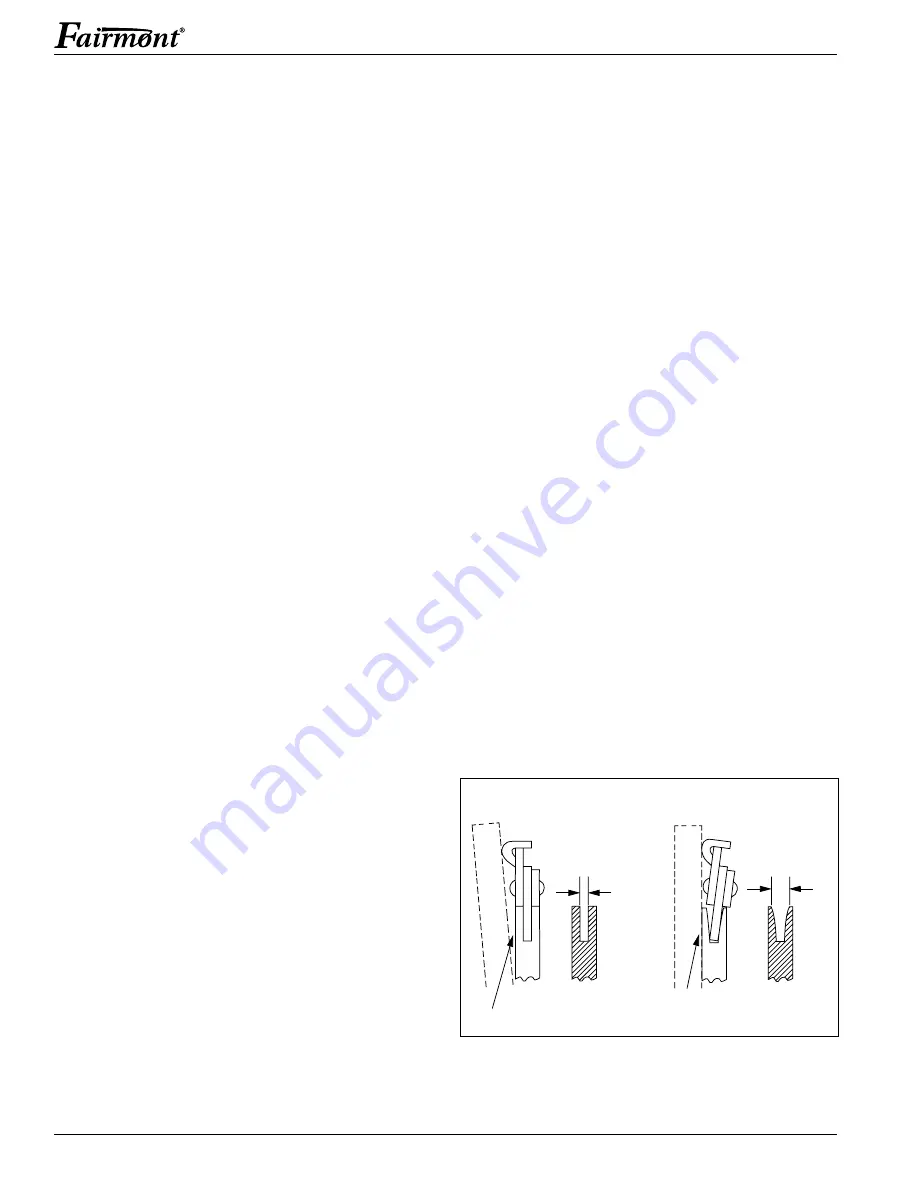

Checking the Rails for Wear

CHAIN IS STRAIGHT

Rails are

not worn.

Clearance

STRAIGHTEDGE

Rails are worn.

Replace bar.

CHAIN LEANS

No

Clearance

STRAIGHTEDGE

6.

Inspect all other disassembled components for

cracks, grooves or nicks.

Disassembly (cont’d)

Oil Metering Screw

Remove the oil metering screw (30) from the saw head

(1). Remove the O-ring (31) from the metering screw.

Saw Head Body/Mount Plate

1.

Remove the four 1/4–20 x .625 button head cap

screws (43) to remove the saw head body (1) from

the mount plate (20).

2.

Remove the two standoffs (46) and two 5/16–18 x 1"

studs (50) from the mount plate (20), only if necessary.

3.

Remove one 1/4–20 x .625 (43) and one 1/4–20 x

.750 (38) button head cap screw and one 1/4–20

lock nut (4) to remove the spike rack (41) and chain

catcher (61) from the mount plate (20), only if

necessary.

Saw Head and Motor

1.

Scribe a line across the motor cap (22) and saw

head motor body (1) to align the parts correctly

during reassembly.

2.

Remove eight 1/4 x 1" socket head cap screws (21).

Pull the motor cap (22) from the saw head motor

body (1). Remove the gasket (25).

3.

Pull the idler shaft (27) with the gear (26) out of the

saw head motor body. Remove the gear (26) from

the idler shaft (27). Remove the drive pin (28) from

the idler shaft, if necessary.

4.

Remove the gear (26) and Woodruff key (33) from

the drive shaft (32).

5.

Remove the 1-3/8" internal retaining ring (36).

Remove the drive shaft (32) and bearing (35) from

the bar side of the saw head. The bearing is

pressed in. Remove the bearing (35) from the drive

shaft (32), only if necessary.

6.

Pull the two dowel pins (23) out of the saw head

motor body, only if necessary.

7.

Remove the O-ring (29) in the saw head motor body

(1). The O-ring can be removed with the needle

bearing (24) in place using an O-ring tool.