CALIBRATIONS / ADJUSTMENTS

Reverse Acting Mode Adjustment

Equipment Required for Calibration:

•

Pneumatic Supply capable of delivering up to 150 psig.

•

Current Supply capable of delivering up to 60 mA.

•

Pressure Gage capable of a digital readout up to 50 psig

with an accuracy of .1%.

•

Digital Volt Meter capable of a readout up to 60 mA with

an accuracy of .02%.

FULL RANGE OPERATION

CAUTION: Over-ranging the Zero Screw can damage unit.

Forward Acting Mode Adjustment

1.

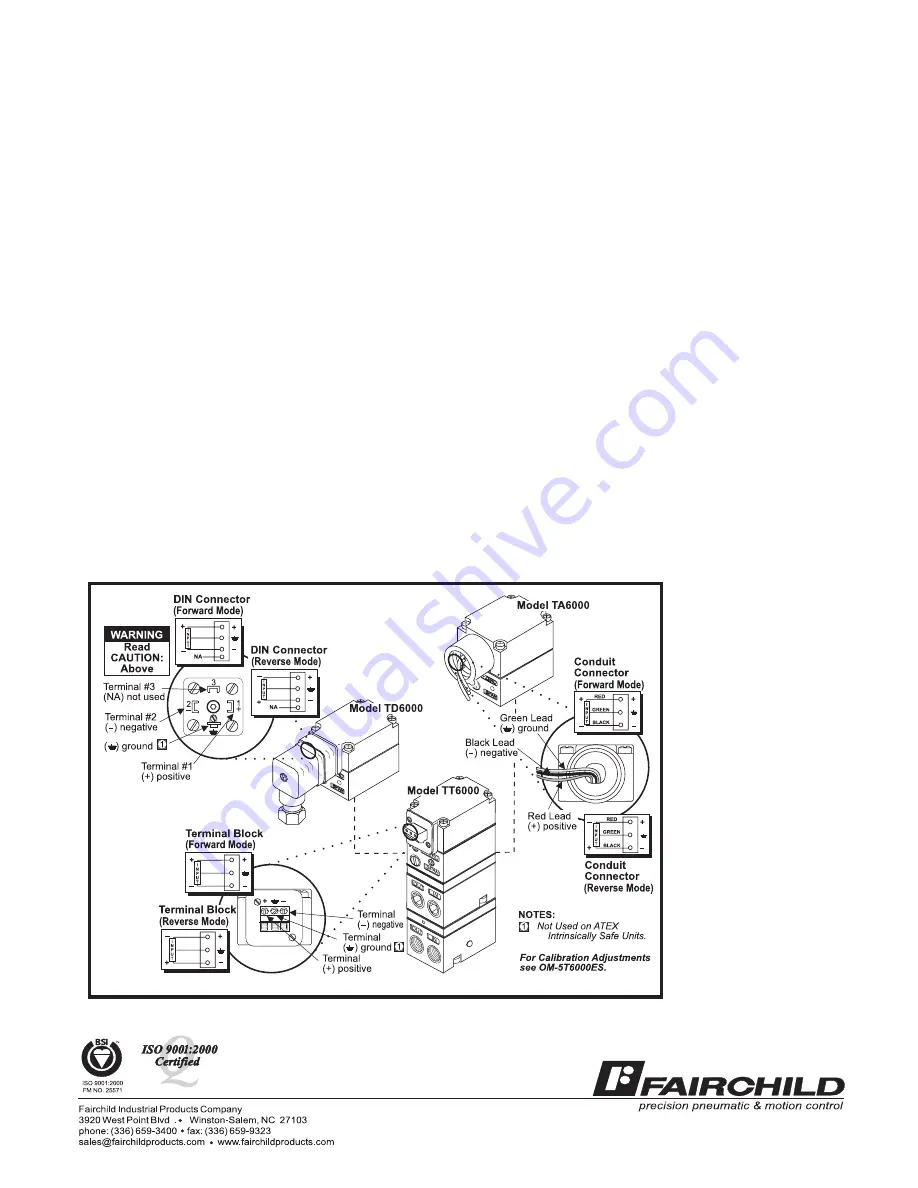

Connect the input signal to the transducer as shown

in the Installation Instructions, II-50T6000X.

•

Forward Acting Calibration-Zero

2.

Apply the minimum input signal and adjust the Zero

screw for minimum output pressure. Turn screw

clockwise to increase pressure and counterclock

wise to decrease pressure.

•

Forward Acting Calibration-Span

3.

Apply the maximum input signal and adjust the Span

screw for maximum output pressure. Turn screw

clockwise to increase pressure and counterclock

wise to decrease pressure.

4.

Repeat steps 2-3 until the desired output range is

obtained. For detailed information, see Figure 1

“TXPD6000 Calibration Configuration” on page 1.

5.

Connect the input signal to the transducer as shown

in the Installation Instructions, II-50T6000X.

•

Reverse Acting Calibration-Zero

6.

Apply the minimum input signal and adjust the Zero

screw for maximum output pressure. Turn screw

clockwise to increase pressure and counterclock

wise to decrease pressure.

•

Reverse Acting Calibration-Span

7.

Apply the maximum input signal and adjust the Span

screw for minimum output pressure. Turn screw

clockwise to decrease pressure and counterclock

wise to increase pressure.

8.

Repeat steps 6-7 until the desired output range is

obtained. For detailed information, see Figure 1

“TXPD6000 Calibration Configuration” on page 1.

SPLIT RANGE OPERATION

All units have the capability to be split ranged or set for any

output in the range as long as the Output Span is equal to

or greater than the minimum Span.

ATEX Directive - Special

Conditions for Safe Use:

The enclosure is manufactured from aluminum alloy. In rare

cases, ignition sources due to impact and friction sparks could

occur. This shall be considered when the equipment is installed in

locations that specifically require Group II, category 1G equipment.

LEGAL NOTICE:

The information set

forth in the foregoing

Operation and Mainte

nance Instructions

shall not be modified

or amended in any re

spect without prior

written consent of

Fairchild Industrial

Products Company. In

addition, the informa

tion set forth herein

shall be furnished with

each product sold in

corporating Fairchild's

unit as a component

thereof.

II-5T6000ES

Litho in USA

Rev. F 06/07