EN

MALFUNCTIONS OR BREAKDOWN

If your water heater presents any malfunctions, immediately disconnect the device from the electrical power supply.

Report to the Technical Assistance Service.

In order to facilitate the tasks of the Technical Assistance Service, please provide the following data:

– Heater model.

– Series number.

– Purchase date.

– Description of the problem.

– Address and phone number.

– Full name of the contact person.

INSTALLATION

ACCESORIES

This electric water heater includes the basic installation elements which are found in the packaging, i.e.:

– Insulating bushing for pipes.

– Safety valve.

The accessories are located within the packaging.

WALL MOUNTING PROCEDURE

Both the wall and the screws and Rawl-plugs should be capable of withstanding the weight produced by a totally full

heater. In case of low thickness walls, the wall should be reinforced.

NOTE.- The placement of the heater must allow access to the supply cable.

LOCATION

The installation procedure is greatly facilitated by being able to locate the unit horizontally or vertically anywhere in the

house.

It is advisable, however, to situate the unit as close as possible to where the hot water is to be used as pipe length

reduction allows water temperature losses to be prevented.

A minimum 0,5 m space should be left underneath the pipe outlet for servicing.

As shown in the drawing 1, when installed horizontally, the input and output pipes must be located on the left.

Should the unit be close to a wall, leave the minimum recommended space for maintenance and servicing operations.

Don’t install the heater with its wall mounts againts the floor nor on a horizontal plane.

HYDRAULIC INSTALATION

NOTE FOR INSTALLERS: the insulating sleeves found inside the packaging, must be located on the inlet/outlet

pipes, using teflon on the screw of the pipes. Tightening torque for sleeves: 3.5Kg/m.

Before proceeding to the hydraulic connexion, please rinse the connecting pipe in the order to avoid filth from

entering inside the electric water heater.

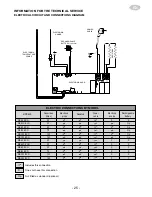

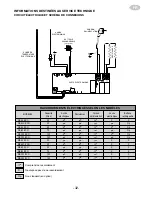

Install the water heater according to the diagrams in figure 1

a) The safety valve supplied with the heater

MUST BE INSTALLED

on the cold water input pipe.

No other hydraulic accessory can be installed between the safety valve and the cold water inlet pipe.

The outlet of the safety valve must be connected to a drain, whose diameter should be at least identical to inlet pipe. The

inclination must be continuous and open, keeping a minimum distance of 20mm., as shown in Figure 1.

This pipe must

be installed in an environment where freeze is not possible and with a downward slope. Water expands when

heated, leaking

(at leats a 3% per heating cycle). Do not worry, this is a standard phenomenon.

To empty the heater, operate the safety group hoisting the lever as shown on figure 2.

We should act on said lever periodi-

cally to prevent it locks and check for proper operation.

b) If the water-supply pressure exceeds 5 bars, a type-approved reducing valve (between 3 or 4 bars) must be installed.

c) In case of plastic piping in the system, please take into account pressure and temperature conditions. Maximum pressu-

re 9 bars and 70°C maximum temperature in standard conditions or 100°C in abnormal conditions when the safety

thermostat cuts the energy supply.

- 21 -

Содержание CB-100 ECO

Страница 63: ... 63 AR ...

Страница 64: ... 64 AR ...

Страница 65: ...AR 65 ...

Страница 66: ... 66 AR ...

Страница 67: ... 67 AR ...

Страница 68: ... 68 AR ...

Страница 69: ... 69 AR ...