14

ENGLISH

1.1. MAXIMUM DUTY CYCLE CURVE

The curve allows the maximum working time (T) to be

obtained as a function of duty cycle (F).

E.g.: The 620 rapid, 640, 642 R/40 and 642/70 operators can

work continuously with a 100% duty cycle, because they

are equipped with a cooling fan. The 620 standard and

642 std/40 models can work continuously with a 70% duty

cycle.

To ensure good operation, keep to the field of operation

lying below the curve.

Diagram of duty cycle

10

20

30

40

50

60

70

80

90

100

0

1

2

3

4

5

6

7

8

9

10

10

11

12

Percentuale

di lav. %

Tiempo (h)

% Duty cycle

% Fréquence

d'utilisation

% Benutzungs-

frequenz

% Frecuencia

de utilización

Zeit (Std.)

Temps (h)

Time (h)

Tempo (h)

620 / 642 RAP.

640 STD.

620 STD.

642 STD.

Notes:

1)

Use suitable rigid and/or flexible conduits for installation

of the electrical cables.

2)

Always route the low voltage accessory connection

cables separately from the 230 V~ power supply cables.

Use separate sheaths to avoid any interference.

a

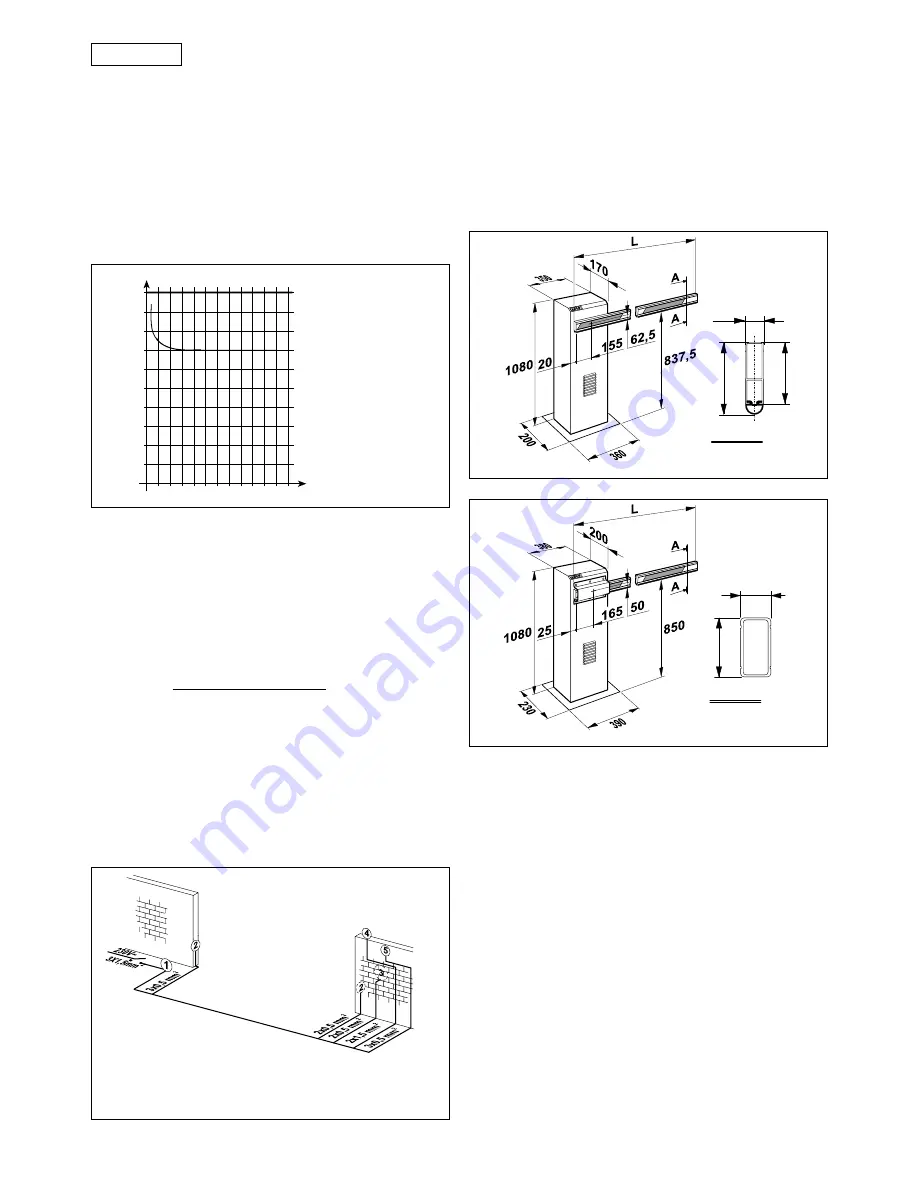

Mod.620 / 640 / 642 barriers

b

Photocells

c

Key switch

d

Flashing light

e

Receiver

Fig. 3

4. INSTALLATING THE SYSTEM

4.1. PRELIMINARY CHECKS

For safe, correct operation of the automation system,

make sure that the following requirements are met:

•

During its movement the beam does not strike against

obstacles or overhead power cables.

•

The characteristics of the ground must ensure sufficient

support for the foundation plinth.

•

There must be no pipes or electrical cables in the area

to be dug for installing the foundation plinth.

•

If the housing is located in a vehicle transit area, it is a

good idea to provide protection against accidental

collisions.

•

Check that the housing is provided with an efficient

earth connection.

4.2. INSTALLING THE BASE PLATE

1)

Assemble the base plate, as shown in Figure. 6.

2)

Prepare a foundation plinth as shown in Fig. 7 (for soft

ground).

Values are expressed in mm.

Fig. 4

25

105,3

90

Sez. A-A

Values are expressed in mm.

Fig. 5

50

100

Sez. A-A

Important:

The curve refers to a temperature of 24°C.

Exposure to direct sunlight can result in a reduction in duty

cycle to as low as 20%.

Calculating duty cycle

The duty cycle is the percentage of effective working time

(o closing) with respect to the total cycle time

(o c pause times).

It is calculated using the following formula:

Ta + Tc

%F =

X 100

Ta + Tc + Tp + Ti

where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti

= interval between a complete cycle and the next.

2. STANDARD INSTALLATION LAYOUT

3. DIMENSIONS